Any outlet that serves cooked food will definitely utilise oil although some more than others, especially at eateries serving many deep fried items in their menu. Used oil may be liquid in nature but as it congeals and hardens, it sticks to the lining of drainage pipes and builds up spacing. This restricts the flow of wastewater that eventually causes blocked pipes, leading to flooded sewers, odour problems and the risk of rat infestations, both within or nearby your premises. Therefore, every establishment needs to have a system to handle the FOGs responsibly and it is a regulation in most countries.

In the foodservice industry, oil and grease can be classified in four forms1:

• Chemically Emulsified: oil that is broken down into small particles using a detergent and does not float to the surface.

• Dissolved: oil dissolved in water with a degreasing compound and does not separate from water

• Free: oil is not dissolved or chemically emulsified but will float to the water’s surface when given time to congeal

• Mechanically Emulsified: free oil agitated in water to form small droplets which will congeal with time.

1 Section 12. Guidelines for Design, Installation, and Construction of Food Establishments in

North Carolina.www.charmeck.org

COMMONLY USED EQUIPMENT TO MANAGE FOGs

GREASE TRAP

Placed in drain pipes, they allow wastewater to flow to sewerage for treatment and grease is retained in the trap and collected by the waste oil collector. As wastewater passes through the trap, any free or mechanically emulsified oil will float to the top as food particles pass through. The size of a grease trap is determined by the estimated volume of water passing through and the type of food cooked; and its capacity typically ranges from 35 litre up to 45,000 litres and above. Generally, there are three types of grease traps:

Hydromechanical

Relying on the principles of heat and gravity to separate FOGs from the waste water, they are usually made of carbon steel or plastic. It controls the flow of water, therefore allowing the hot water to cool. As FOGs is denser than water, it can settle out of the water and sink while the baffles catch the FOGs to keep it inside the trap.

Automatic Grease Removal Unit (AGRU)**

FOGs is skimmed out of the water with mechanical and electrical components and most can eliminate 99% of FOGs from water. Many AGRU traps are fitted with an internal collection device to catch food particles, a heating element and an external FOGs collection unit. They come in sizes that can be placed under a sink or even accommodate larger kitchens. While pricier, maintenance is less of a hassle.

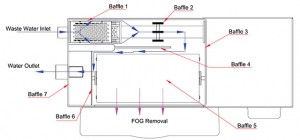

• Waste water inlet: connects kitchen fixtures with drainage function to the grease trap.

• Baffles: Retains grease toward the upstream end instead of it moving further downstream to cause blockages.

• FOG Removal: Area where oil and grease accumulates behind baffles and floats on the water’s surface to be removed during cleaning of grease trap.

• Water Outlet: Exit point for the water to continue on to the grease interceptor or sewerage system.

**The illustration depicted above is the model of GreaseShieldTM grease trap, provided by EPAS-Ltd. Models from other manufacturers of grease traps may differ.

Gravity

Using two or more compartments, it also uses more flowing water to slow down the water inside the trap so that FOGs get buoyant and separates. This option would be more applicable for bigger kitchens as sizing are expressed in gallons of FOGs it can hold.

ENZYME DOSING2

Designed to treat fat and grease in the drainage system and can be used with grease traps although in some cases, unnecessary if proper measures are taken to keep FOGs out of drains in the first place.

The everyday actions of the kitchen crew can make a difference in the way FOGs are managed:

• Wipe and scrape down cutler y and utensils to get rid of any food waste and oils before washing.

• Ensure that sink holes are fitted with strainers to catch any small particles that were not discarded.

• Use suitable containers to keep used oil and work with a licensed contractor to pick them up. Depending on the country of your operations, management and regulations of used oil disposal may differ.

• Avoid sweeping food waste down the drainage system.

2 Water UK. Disposal of Fats, Oils, Grease and Food Waste. Best Management Practice for Catering Outlets

MANAGING VAPOUR

Cooking grease is not limited to what’s left on utensils but includes grease vapour that makes the working environment humid and uncomfortable; not to mention the sticky and oily elements that settle on surfaces of other equipment. Therefore, kitchens need an exhaust system to remove the greasy vapour where the canopy captures the vapour emitted from the stovetops. The placing of an exhaust canopy can be wall-mounted, island type, back shelf or installed directly over cooking appliances. You will need to first identify what types of cooking appliances and food preparation methods are applied in the kitchen.

Type 1 hoods are suitable for kitchens with many grease producing appliances and methods such as grilling, frying, and smoking while Type 2 are generally for removal of steam vapours and heat caused by high temperature dishwashers. Exhaust hoods will trap the grease vapours but if you do not clean its filters; it would soon cease to work properly. The grease filters can be cleaned periodically by your own crew but for the duct, a professional should be called in as it is dangerous and hazardous if not done properly. A duct is essential for kitchens located in mixed commercial buildings to ensure that greasy air does not permeate into air conditioned environments. Installing ducts require acute calculation as the force of its suction depends on the motor and building’s structure.

Type 1 hoods are suitable for kitchens with many grease producing appliances and methods such as grilling, frying, and smoking while Type 2 are generally for removal of steam vapours and heat caused by high temperature dishwashers. Exhaust hoods will trap the grease vapours but if you do not clean its filters; it would soon cease to work properly. The grease filters can be cleaned periodically by your own crew but for the duct, a professional should be called in as it is dangerous and hazardous if not done properly. A duct is essential for kitchens located in mixed commercial buildings to ensure that greasy air does not permeate into air conditioned environments. Installing ducts require acute calculation as the force of its suction depends on the motor and building’s structure.

In conclusion; fats, oils and grease are part and parcel of any kitchen and it is crucial to manage it not only for a conducive working environment but to keep other equipment running smoothly because the build-up of oily vapours can spoil a machine in the long run. Regular maintenance of FOG-related equipment will keep your operating cost low when you have prevented the need to call a professional to unclog the pipes and drains or check other equipment affected by FOGs.