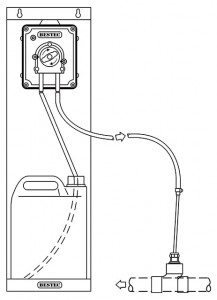

Example of an ADU installation for an undercounter grease trap

The unsavoury task of grease trap maintenance has often left many food business owners spending more to clear blockages from the build-up of FOGs. Following up from our previous issue’s highlight on grease trap (also known as interceptor) maintenance, dosing can be an added consideration to the regime. Not as a substitute for washing but as an assistance. This is because, when the kitchen is in operation, water is constantly pumped into the trap and the presence of oxygen will create a reaction that separate the fats, oils and grease particles from water. The water that flows out into the sewerage system will then be free from particles that can clog pipes. However, when water is not flowing into the grease interceptor, installing an Automatic Dosing Unit (ADU) can help to continue the process of separation.

Close-up of the ADU

A liquid cleaning agent, usually referred to as enzyme is dispersed through the ADU; which releases the liquid in small quantities into the grease trap at specific intervals to create the similar reaction when water is not flowing. Dosing units are automated to disperse the enzyme with a peristaltic pump, electric wiring and supply tube connected from the enzyme container to an inlet drilled into the grease trap. An ADU is easy to set-up by cutting the tube according to the length required from the container of the chemical storage to both the inlet and outlet of the unit and towards the drain or the grease trap. The interval of dosing and amount of enzyme dispersed each time is calculated according to the size of the grease trap which is dependent on volume of food served and type of cooking done; whether heavy grease or otherwise.

A drawing of the BESTEC brand

ADU by Weimar

An important point to note – ADUs are not the solution to grease trap maintenance as some might think it eliminates the often unwanted job of cleaning the interceptor. It is an optional assistant that can help owners better maintain the fat, oil and grease-related equipment by breaking down fats into smaller particles at a more rapid rate, says Ms Tan Yoke Ching of Weimar Enterprise Sdn. Bhd. Therefore, following a maintenance schedule is still extremely important, she said, adding that the company provides a complete solution to the grease issue in commercial kitchens; from sizing the interceptor, fabricating it, installing ADU and maintenance. Although manual washing can be carried out by the kitchen crew, Weimar’s team uses wet and dry vacuum cleaners to do a more thorough job along with cleaning the pipes. They will also ensure that the solids gathered from the grease interceptor is properly packed and sent to companies that can use it to produce bio-diesel; an alternative energy resource.

** Special thanks to Weimar Enterprise Sdn Bhd for providing information and photos regarding Automatic Dosing Units (ADU) and grease traps.