Axel Wenner-Gren

No stranger to many commercial kitchens around the world, its brand manifesto “Thinking Of You” puts into words what was practiced decades ago by its founder itself. How long and what does it take for a company to develop and successfully hold its ground in both domestic and commercial markets? It is always about seeing the opportunity and providing the solution to meet the needs for people to carry out tasks in an easier manner.

When Axel Wenner-Gren came across a Santo vacuum cleaner in Vienna in 1908, he saw that every home could benefit from this machine yet the question was, how would they see the point? His solution was to bring the machine to them, run a product demonstration and offer an instalment purchase plan. With the idea, he contacted Santo, an American company, and offered to act as the European representative and he was tasked to work with its existing general agent and eventually led the Santo Staubsaug Apparate Gesellschaft in Berlin.

After his stint, he returned to Sweden and sought out the local Lux Company to be its agent for the new Lux 1 vacuum cleaner in Germany, United Kingdom and France. He started his home sales run in Sweden by setting up meetings with housewives and their husband (usually the breadwinner) before pulling the heavy machine through streets to their home to conduct the demonstration.

The first Lux 1 vacuum cleaner

Realising that “Lux 1” machine was rather cumbersome and with adequate understanding on vacuum cleaners, he suggested a smaller and portable machine that uses a universal motor, developed by Aktiebolaget Elektromekaniska which also made motors for “Lux I”. He presented the new model to Lux but the company was sceptical. A blessing in disguise, perhaps, as Wenner-Gren then started Svenska Elektron AB company to sell the new vacuum cleaner and as his good run continued, he bought a major block of Elektromekaniska shares followed by a merger with AB Lux for its production capacity. In 1919, it was consolidated to AB Elektrolux – a combination of Elektromekaniska, Elektron and Lux.

Moving ahead, under the chairmanship of Hans Werthén, acquisitions and diversifications were carried out as he thought the company too small compared to competitors yet too big to stick to niche products. On the humanistic side, he developed the “Lux culture”, defined by businesslike, market-driven approaches, cost-efficiency and quick decisions that kept to very minimal bureaucracy. Werthén was also one for building rapport by endeavouring to answer his own telephone calls.

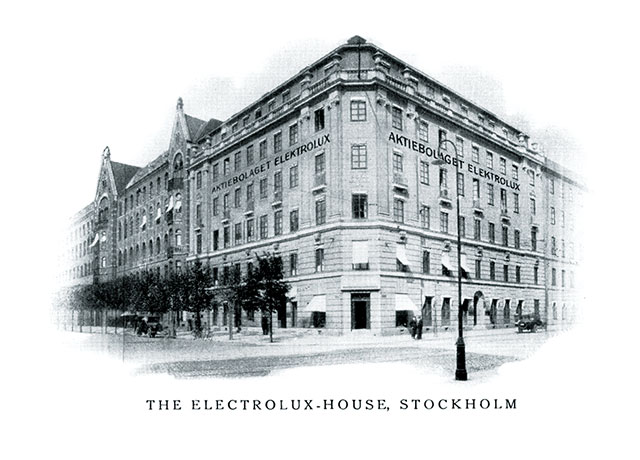

First head office

Electrolux’s headquarters today

The company was on towards a bright future as it bought a good number of companies to start new distribution channels and a step for it to become the Electrolux Group in the 1980s. While vacuum cleaners were core of its operations, it began making industrial products for commercial cleaning and service operations, hence bringing Electrolux Professional to the fore.

Ensuring a no-glitch kitchen

A COMMITMENT TO CONNECT AND CREATE PARTNERSHIPS

Every foodservice professional knows the importance of service after the purchase point. Because “Thinking of You” motivates each decision and area of its operations, the Service Excellence department comprises the A-Z of a customer’s investment. It starts with understanding clients’ concerns and needs then helping to select the most appropriate machine according to the layout before installation and training. The after-sales is standardised on a global scale with 2,000 authorised service centers in over 140 countries working with a network of 10,000 expert technicians to meet scheduled maintenance or ad-hoc servicing needs. Its spare parts stock amounts to up to 98,000 pieces with worldwide delivery within 24-48 hours and is available for at least 10 years even though production of a certain machine has ceased.

Taking it further, the Chef Academy is a place where customers are invited to experience Electrolux Professional in person. This helps in providing clarity and gives users an edge on how they can maximise the equipment for an improved workflow and profit. Its total of 14 Centers of Excellence in Europe, Asia and the USA is fitted with showrooms and live demo kitchens; and in-house chefs always available to assist. Its Italy Center of Excellence is the largest at 3,500 sq.m housing four training kitchens that clocks up to 40,000 hours of teaching per year. For those who are unable to be at the Centers of Excellence, Electrolux has given due thought and developed e-learning programmes for them. Product introductions and updates are also extended to dealers and associates so that everyone is on the same page especially regarding the evolution of technology in the equipment.

To further reach out to professionals, the company has recently started collaborating with WORLDCHEFS; the global network of chefs associations founded in 1928 with the aim of sharing common knowledge and increase awareness on the topics of sustainable cooking. WORLDCHEFS has a total of 93 official chef associations as its members that represent over 10 million professional chefs worldwide and has a board of directors to look after the regions of Asia, Europe, Africa, the Pacific and the Americas. Together with Electrolux, they have come up with the “Art & Science Come Together” program – a potential of discoveries when culinary creativity and talent of WACS chefs meet insights, technology and specialised experience of Electrolux Professional. Marking the start of the program is Chef2Chef; a series of seminars where chefs gather at the Electrolux Professional Centers of Excellence to explore further core themes that affect the industry such as sustainability from sourcing ingredients to cooking backed by technology and science of the Cook&Chill system, for example. Beginning in four key areas of Dubai, Russia, United Kingdom and United States, both parties are working to involve more countries in time to come.

A buzz in the Center of Excellence

THE EQUATION OF SUCCESS

Technology in product development has come a long way and while restaurants could still get by on manual work as eating out was a luxury in the past, today’s scenario is vastly different and any assistance is much appreciated and even, non-negotiable for some. In the scenario painted by Electrolux Professional, “imagine..a Formula One driver without his high performance car”, a sound reason for its relentless pursuit of making a positive difference with the right tools and instruments.

At the same time, products cannot sell itself just standing in the shops; they need to also be brought out to the masses as it dawned upon Axel Wenner-Gren. Electrolux has found that there is no element greater than the other, which has definitely worked in its favour for

90 odd years that it has served homes and commercial facilities.

The complex made easy for users

A RANGE TO MEET THE INDUSTRY’S EVERY NEED

Cooking systems

Individual preferences are taken into account through modular cooking systems that has been developed since the 1960s offering flexibility and productivity for chefs. The work continues with thermaline able to better customise work stations by up to 40 different options for today’s varied eating cultures. Its intelligent design has been awarded the coveted Red Dot Award for Product Design 2014 putting it in the ranks of the 1.5% of recipients amongst 5,000 entries. The jury of 40 international level design experts decided the exclusive design of thermaline M2M with the free cooking ability where a new free-cooking top allows use of both pots and pans to cook food directly on contact, simultaneously meeting the Red Dot standard of excellence. Precision is also at the heart of this system which can be fixed with an accuracy of up to 1°. For the modular product line, its 900XP and 700XP stoves are built by studying and anticipating the needs of a chef in quick and full service restaurants or high productivity kitchens. Due to the rigours of a demanding kitchen, a new high

power Induction Top and woks are low heat emitting yet improves performance. Together with Electric Hob Top, smaller but labour-heavy kitchens can work better while “flower flame” burners have a unique shape to allow the flame to be precisely adjusted and fit pans of any diameter.

thermaline – Modular 80 & 90

Unique cooktops serve the niche eatery but what about high volume cooking? Based on the fundamental concept of simplicity, each air-o-steam Touchline combination ovens is intuitive, clear and user-friendly despite the complexity behind its engineering. As we all know, kitchen space is a luxury to be afforded these days and yet business owners consider equipment to be indispensable. This is a challenging time for manufacturers to help their clients maximise the space without watering down their productivity. Hence, Electrolux brings to the fore its Cook&Chill air-o-system that combines a combi oven and blast chiller to fully cook food, followed by rapid blast chilling at controlled temperatures and regeneration for service. This integration takes up less floor space and also allows for more effective time and resource management. When it comes to the condition of a cooking chamber, the principle is “more air, less steam” which can affect the moisture of food. With its patented Lambda sensor, users will have precise control of the cooking climate in the chamber (humidity generated by the food itself is also considered). The crucial role of the Lambda sensor is to prevent water droplets due to condensation from ending up on plates and avoiding imperfect cooking.

Unique cooktops serve the niche eatery but what about high volume cooking? Based on the fundamental concept of simplicity, each air-o-steam Touchline combination ovens is intuitive, clear and user-friendly despite the complexity behind its engineering. As we all know, kitchen space is a luxury to be afforded these days and yet business owners consider equipment to be indispensable. This is a challenging time for manufacturers to help their clients maximise the space without watering down their productivity. Hence, Electrolux brings to the fore its Cook&Chill air-o-system that combines a combi oven and blast chiller to fully cook food, followed by rapid blast chilling at controlled temperatures and regeneration for service. This integration takes up less floor space and also allows for more effective time and resource management. When it comes to the condition of a cooking chamber, the principle is “more air, less steam” which can affect the moisture of food. With its patented Lambda sensor, users will have precise control of the cooking climate in the chamber (humidity generated by the food itself is also considered). The crucial role of the Lambda sensor is to prevent water droplets due to condensation from ending up on plates and avoiding imperfect cooking.

Dynamic Preparation

When a manufacturer chooses to be diversified, it should also offer complementary solutions to complete the picture such as the TRS and TRK vegetable slicers/food processors that make work a snap with just the changing of blades and turning of the switch. Or instantly whisk up creams, soups, batter mixes and purees with the handheld portable mixer that goes straight into the pot instead of pouring the liquid into regular processors. For banqueting or any other large scale cooking purposes, a vegetable washer and dryer will take out all the manual labour and time needed to wash them meticulously.

Refrigeration

The new ecostore cabinets are made to provide 50 litres more storage space than usual yet its size advantage still manages a low energy consumption and is equipped with Frost Watch Control that activates the defrost cycle only when necessary. Blast chillers and freezers

are crucial for optimum food preservation such as soft chilling for delicate items, hard chilling for solids like stews and meats while blast (shock) freezing is purposed for raw, half and fully cooked foods to be stored longer. The range of blast chillers are also designed to

match the Cook&Chill system.

Dishwashing

The resource consuming task of dishwashing is made more efficient with the green&clean hood type dishwashers. It does not require additional ventilation with ESD Energy Saving Device as it uses generated steam to pre-heat water while WASH·SAFE CONTROL

utilises atmospheric circuit with cold water to ensure top notch washing. The ZERO LIME Device is an automatic de-lime cycle that maintains the boiler, hydraulic circuit, nozzles, heating elements and washing chamber from scale build-up so that the dishwasher is not using extra resources to eliminate the scale.

Laundry Solutions

From the kitchen to the laundry area, Electrolux has got it covered, meeting the demanding needs of professional laundry business from hospitality, healthcare and commercial laundries with its Line 5000 series washer extractors and tumble dryers. To contribute to the customers’ profitability, the Automatic Saving and Efficient Dosing Systems on washers and Residual Moisture Control on Dryers saves water, energy and detergent. Compass Pro® is the intelligence inside Line 5000 that enables Electrolux to provide customised solutions for ever y kind or laundry business, offering up to 55 programs. The leading manufacturer in the world that excel on complete solutions for the foodservice and laundry industry, Electrolux’s products are founded upon the idea of “from Customer insight to Excellence inside” where customers’ need become the company’s direction to create intelligent and field-tested features to make work easier and more profitable.

For more information on Electrolux’s full range of solutions, visit

www.electrolux.com/professional