Imagine a fully automated kitchen and remote operations. It could very well happen as certain equipment already have such function and if Metos’ guiding idea is kitchen intelligence; it would not be surprising that this kitchen comes to pass. What comes to mind upon the word “intelligence”? Simply put, it is the ability to learn or understand a new or challenging situation followed by the ability to apply knowledge to manipulate the situation. And this very definition suits Metos to a tee.

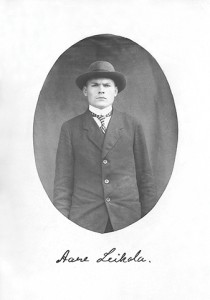

The knowledge of what commercial kitchens need has resulted in a complete range of product offerings – from preparation all the way to hygiene and for any production capacities. Kitchen equipment is an end result but what Metos star ted off with was possessing the know-how of metal and ways to use it. Knowledge and application were essential considering that founder Aare Leikola was a former teacher at University of Tehnology and the Helsinki Industrial School prior to being involved in manufacturing. In 1922 Aare Leikola and partners started Oy Metalliteos to mass produce metal items and their first customers was the Finnish Army that ordered lion buttons.

As they continued to experiment with metal, they soon mastered stainless steel and made table tops for professional kitchens. This means a high regard for hygiene and durability in its quality stainless and acid-proof steel. Progress was steady as it delivered cooking pots, the world’s first factor y-made electric sauna heater and just before the Winter War of 1939, Metos had delivered a complete range of kitchen equipment to a Alko Salmisaari kitchen. It must have garnered attention because the company was then selected to make equipment for the Helsinki Summer Olympics in 1940. Unfortunately, the Olympics didn’t take place due to war but the equipment would go on to serve the local food supply centre, and some, like pots for more than 40 years! Also, in a time of duress and uncertainty of war; anyone would do anything within their capacity to weather through. Hence Metos made ski bindings, tent stoves for the army and consumer items like steel money boxes.

As they continued to experiment with metal, they soon mastered stainless steel and made table tops for professional kitchens. This means a high regard for hygiene and durability in its quality stainless and acid-proof steel. Progress was steady as it delivered cooking pots, the world’s first factor y-made electric sauna heater and just before the Winter War of 1939, Metos had delivered a complete range of kitchen equipment to a Alko Salmisaari kitchen. It must have garnered attention because the company was then selected to make equipment for the Helsinki Summer Olympics in 1940. Unfortunately, the Olympics didn’t take place due to war but the equipment would go on to serve the local food supply centre, and some, like pots for more than 40 years! Also, in a time of duress and uncertainty of war; anyone would do anything within their capacity to weather through. Hence Metos made ski bindings, tent stoves for the army and consumer items like steel money boxes.

THE STAGE OF PROMINENCE

Persistence pays. In 1952, the Helsinki Summer Olympics commenced and it placed faith in Metos once again. The huge order possibly enabled the company to open an equipment exhibition on Yrjönkatu Street in 1956 and its potential attracted Instrumentatium which acquired the majority of shares in 1959 and made Metos a par t of a listed conglomerate. The 60s were a good time with the starting of Metos Service, a regional sales network, the building of the Merivaara and 1967 it made a decision on its direction – focus on professional kitchen equipment

and sauna heaters. The biggest breakthrough in the 70s was the establishment of a separate Marine department and Moscow Summer Olympics came knocking in 1980. It stopped making sauna heaters in 1983 and invested all its energies into hospital and professional kitchen equipment. After undergoing some changes in management and ownership, today Metos has a total of 3 factories – 2 in Finland and 1 in Estonia; totaling 15,000 sqm in space. Two of its factories produce multi -line products. In Kerava, it has 3 manufacturing lines to produce Kettles and Steamers, Distribution and Nordien System Trolleys. The factory in Sorsakoski (Central Finland) focuses exclusively on neutral stainless steel furniture. Meanwhile, its Estonian operation splits its capacity between Metos Classic Cooking assortment and Nordien System tables and caroussel units.

INTELLIGENCE BEYOND EQUIPMENT

Insight is vital to direct what to manufacture and so is foresight to anticipate what might be good for consumers. If we were to illustrate it, we see that Metos proposes a process that has a sensible flow so that customers are fully immersed in their project’s requirements and are not just buying an equipment because someone said so.

• Installation Drawings

An easy-to-use application to design your commercial kitchen, the Metos Professional Kitchen Planner allows customers to visualise a kitchen’s space usage and cost.

• Metos Equipment Symbols

Symbols help kitchen designers who use AutoCAD. Symbols come with technical data and connection points to make things clearer.

• Kitchen Planning

For clients who do not have independent designers, the Metos professionals are able to design any type of food service facility.

• Individual Product Training

Time for practicals. Upon completion of product or project installation, Metos’ domestic chef will be present to teach users how to optimise the use of the equipment.

• Education and Demonstrations

The perfect avenue for users to research is during product presentations and cooking demonstrations by Metos’ chefs at trade shows. In line with this, METOS Center is designed as a meeting place for professionals. Located at Kerava (Finland), Stockholm (Sweden), Riga (Latvia) and Vilna (Lithuania). These centres are equipped with the complete Metos range including kitchen machinery, distribution equipment and table-top products. Customers are encouraged to book a time for training courses, order a customised demonstration, even tr y out own recipes at the cooking facility or simply to find out more about Metos’ solutions.

• After – Sales Service

A prudent entrepreneur would select products where the he / she can expect swift post-sales response. In Finland alone, Metos has over 100 servicemen and a mobile service system that covers the most common spare parts in 23 areas so that customers can potentially get back on track within 24 hours. Service contracts and kitchen analysis exercises are available to ensure your kitchen operates properly. It also ensures that international partners and subsidiaries are well-equipped with spare par ts and technical support as service training is provided to servicemen. Spare parts for Metos equipment are available for a minimum of ten years.

MANUFACTURING WITH CARE

A vast industry with many needs. Do we mindlessly produce or do we do it with responsibility? Its a challenge that Metos took on. Its holistic approach takes into account the manufacturing process and extends to empowering their customers to work with environmental consciousness in mind as well. Metos teaches customers how to prepare food on a more efficient heat transfer technology with current food preparation equipment that will reduce energy and water consumption alongside improving efficiency.

An example is the ICS operational control system developed for dishwashers; effective in reducing consumption figures thus leaving behind a less damaging carbon footprint. It might take more effort but it is right to minimise waste during production and delivery periods hence it sorts and recycles all waste; especially recycling stainless steel. Believing that using the right materials reduces impact of waste, you are most likely to get a dishwasher manufactured from 90% recyclable materials. In its home country Finland, the company even created a nationwide reception and recycling system that ensures that all recyclable materials find a new life.

Clearly, Metos raises the bar high for itself to achieve Kitchen Intelligence. And bridges the gap between the cold and monochrome stainless steel and human experience; right from the beginning of its production thus paving the way for enduring relationships.