Commercial kitchen equipment are increasingly made for energy efficiency, be it in terms of temperature, water or time factors. While it is possible to measure savings from individual equipment, not every kitchen has the latest machines with such features or have a real need to change to new ones at this moment of time. With these elements in mind, companies have come up with external tools that can help operators monitor how their kitchens are handling energy use.

ENISCOPE PROFESSIONAL REAL-TIME ENERGY MONITORING

Ask any food operator the challenges they are constantly up against and most would give you one single word, that is COST. However, do you know exactly how much energy it takes to power up a fryer or to run an oven? As said by Alan Tan, Director of IETCO Sdn. Bhd., utility bills won’t tell you where energy was used but when costs go up you are unsure what the cause is. Particularly if some buildings do not allow use of gas for safety reasons, you have to go with electricity which definitely costs more and monitoring allows you to be more efficient. With that insight, IETCO brought in ENISCOPE from United Kingdom and proposes to operators the benefits of energy monitoring – in real time and with data, no less. Measurement and verification is the key to convincing customers about applying a metering solution, said Alan.

One of its earliest adopters in Malaysia, KFC has found ENISCOPE to be useful, given how much energy it takes to run a fast food shop for 12 hours (some even 24 hours). It needs constant cooking, heating, air conditioning, lighting and refrigeration. Multiply that by the hundreds of stores KFC has around the country! Staggering figures, indeed. After trying Eniscope in a few pilot outlets and discovering its benefits, KFC began fur ther implementations and is currently using it in more than 100 outlets. According to the client, one of the highlights is the cloud based analytics which allows the headquarters to remotely manage all of its outlets and benchmark performance against each other.

This allows quick troubleshooting and easy implementation of energy saving practices.

How does ENISCOPE work? Do you install it into each machine for monitoring? To our surprise, it could not be easier. The standalone device is mounted on to the fuse box and all the technicians need to do is find out the power source for specific equipment and attach the monitoring clip to the wire. To monitor water usage, you will need to have it connected to a pulse meter. Each ENISCOPE unit is able to monitor up to 8 three-phase channels and provide figures for electricity, gas and water usage all in one central location. Easily accessible via any web-browser or using its smart phone mobile app, you can access real-time data of your kitchen no matter where you are. The collation of daily data allows managers to monitor each piece of equipment, pick up on energy leaks, find out how energy is potentially abused in the kitchen and even check the effectiveness of energy saving products. It is also able to monitor for abnormalities. For example, the refrigerator that is on 24 hours suddenly stops working and when ENISCOPE is not picking up any data, it will send an alert to the operator.

It is also able to corroborate all the data for comparative analysis according to your needs such as comparing outlets’ consumption at a specific time period. Investing in ENISCOPE is based on an initial purchase price and following that, users only need to pay a monthly subscription fee for the software. IETCO is a distributor of ENISCOPE in Malaysia and is en route to expanding its coverage within the region.

For more information on the solution, visit http://ietco.com.my

SMART ENERGY MANAGER

KITCHEN BRAINS’ SCK® SMART ENERGY MANAGER (SEM)

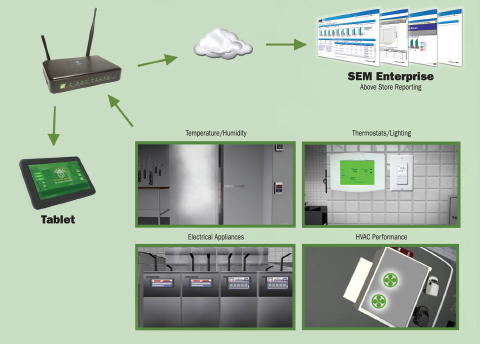

Among Kitchen Brain’s array of software under its Smart Commercial Kitchen’s (SCK) range, SEM fulfills the operators need to monitor every kwH used in the kitchen.

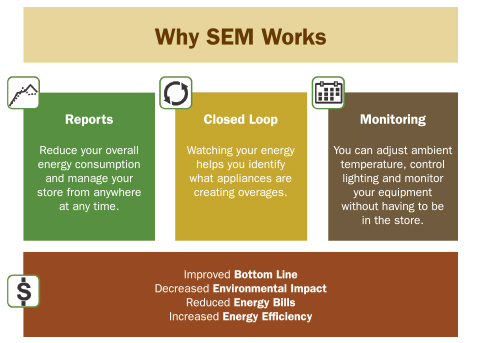

Each time someone turns on an equipment, SEM records the data and monitors the usage. Because repor ts are automatically synced to users’ personal mySCK portal, managers and operators are able to stay abreast with daily operations, ensuring that staff are keeping up with energy management methods. The SEM software is flexible and adaptable to any areas of the restaurant, whether front-of-house and/or back-of-house. The SEM application continuously syncs all data throughout the day thereby providing managers with alerts whether any adjustments to temperatures, lighting or equipment usage method is required.

According to the U.S. Depar tment of Energy, establishments using SEM have been found to enjoy:

ECONOMICS OF SEM

• 60% of all energy consumption is now proactively managed

• 25% savings on total energy used

• Prevention of food spoilage and food safety violations

• Identify problematic equipment from patterns of behavior

• Saves up to 50% on repair costs through elimination of emergency service calls

• Aler ting on equipment malfunctions before failure

• Energy management policy compliance is maintained through continuous monitoring of usage

*U.S. Depar tment of Energy

For more information, visit www.kitchenbrains.com