WASH YOUR HANDS!

At this time, we simply can’t emphasise enough how much this statement is saving lives all around the world. As this article is being prepared, we have close to 3 billion people confined to their homes, more than 460,00 infected worldwide and death tolls are rising daily.

All of the food and beverage industry is reeling from the effects that the virus have into their business. Regardless whether you are a chain, a restaurant or a food stall, confined public never spells as good news. Delivery services are also being pushed to its limit and that is another topic that we covered in another article.

But as we are sequestered in our homes, we got on video conference with Cheryl Wong, Business Development Manager – Chemical Division and Esmen Yee, Marketing manager from SEA office of Winterhalter to find out if 20 seconds under the tap for your staff in a F&B business is enough.

WHO, WHEN, HOW ?

WHO

WHO

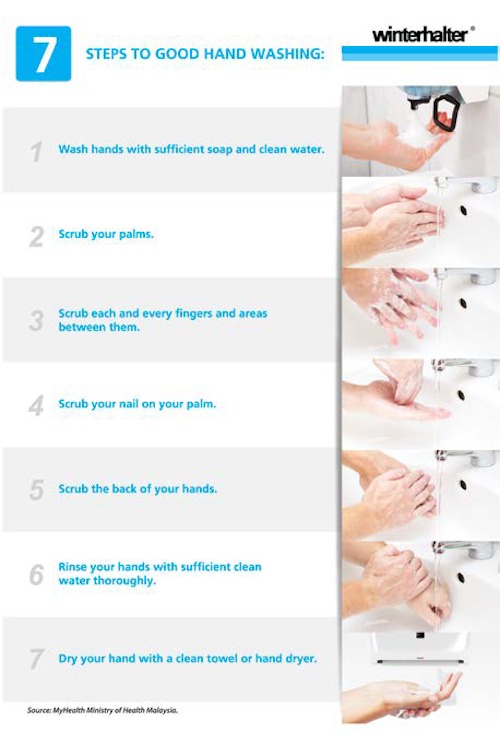

Every food handler should be trained to wash their hands to maintain optimum hygiene. Nearly every surface is covered with microorganisms that we cannot see.

WHEN

Before, during and after. Of course it is compulsory that staff wash their hands after using the rest room, touching the body or clothing, coughing, sneezing, blowing nose or using a handkerchief or tissue, eating, drinking, handling soiled items and etc.

One important point is also because humans habitually like to touch our own face, staff must be aware of their actions during service. (There is an interesting article that encourages you to use your less dominant hands when you need to do something mundane.)

HOW

5 or 7 steps, 20 seconds, soap and water.

But with Cheryl and Esmen on the line, we checked for some facts if this is enough and what businesses could also do better.

PERSONNEL – Hand Washing And Hand Sanitisers.

They both sound clean but operators must understand that staff using just hand sanitisers is not enough. Handwashing with the right antibacterial soap must be done at the very start with hand sanitisers used intermittently during service if your staff is in the kitchen. Though if your staff is handling fresh and raw products, handwashing with soap is still the requirement.

Handwash soap has the necessary component to remove grime and soil. A sanitiser can reduce microorganism but it doesn’t remove soil like oil and grease which if it stays on the hand would present a possibility of cross contamination.

So for the best option, an antibacterial soap is still necessary with sanitisers used periodically throughout service.

Agents For Cleaning And Sanitising Surfaces And Products.

Food safety or Serv Safe compliance would cover every other aspect in the kitchen which ultimate aim is to avoid foodborne – illness outbreaks.

From your tools and utensils to appliances to your food produce, proper hygiene practices are crucial and just like your hands – clean then sanitise is the way to go.

Cleaning removes food and other dirt from a surface. Sanitising reduces pathogens on a surface to safe levels. We must clean and rinse a surface before it can be sanitised. Then the surface must be allowed to air-dry.

Chemicals of various purposes by Winterhalter – C112, C151, C122 and C121

STEP 2 – SANITISING

Sanitising is practiced either using heat or chemical. Each sanitising method and sanitiser chemical has specific requirements for use.

Heat Sanitising: Most dishwashers opt for heat sanitising. With temperatures achieving 82°C during its final rinse, dishes come out sanitised. For effective soaking, you are required to soak them in temperatures higher than 77°C with at least 30 seconds.

Chemical Sanitising

Though most operators now uses dishwashers in their operations, in instance where manual practises are still apparent, a 3 compartment sink – one for each task (clean, rinse, sanitise) should be practiced. In areas where chemical sanitisers are applied, its effectiveness is based on several factors and among them are concentration, temperature, contact time, water hardness and pH.

Though most operators now uses dishwashers in their operations, in instance where manual practises are still apparent, a 3 compartment sink – one for each task (clean, rinse, sanitise) should be practiced. In areas where chemical sanitisers are applied, its effectiveness is based on several factors and among them are concentration, temperature, contact time, water hardness and pH.

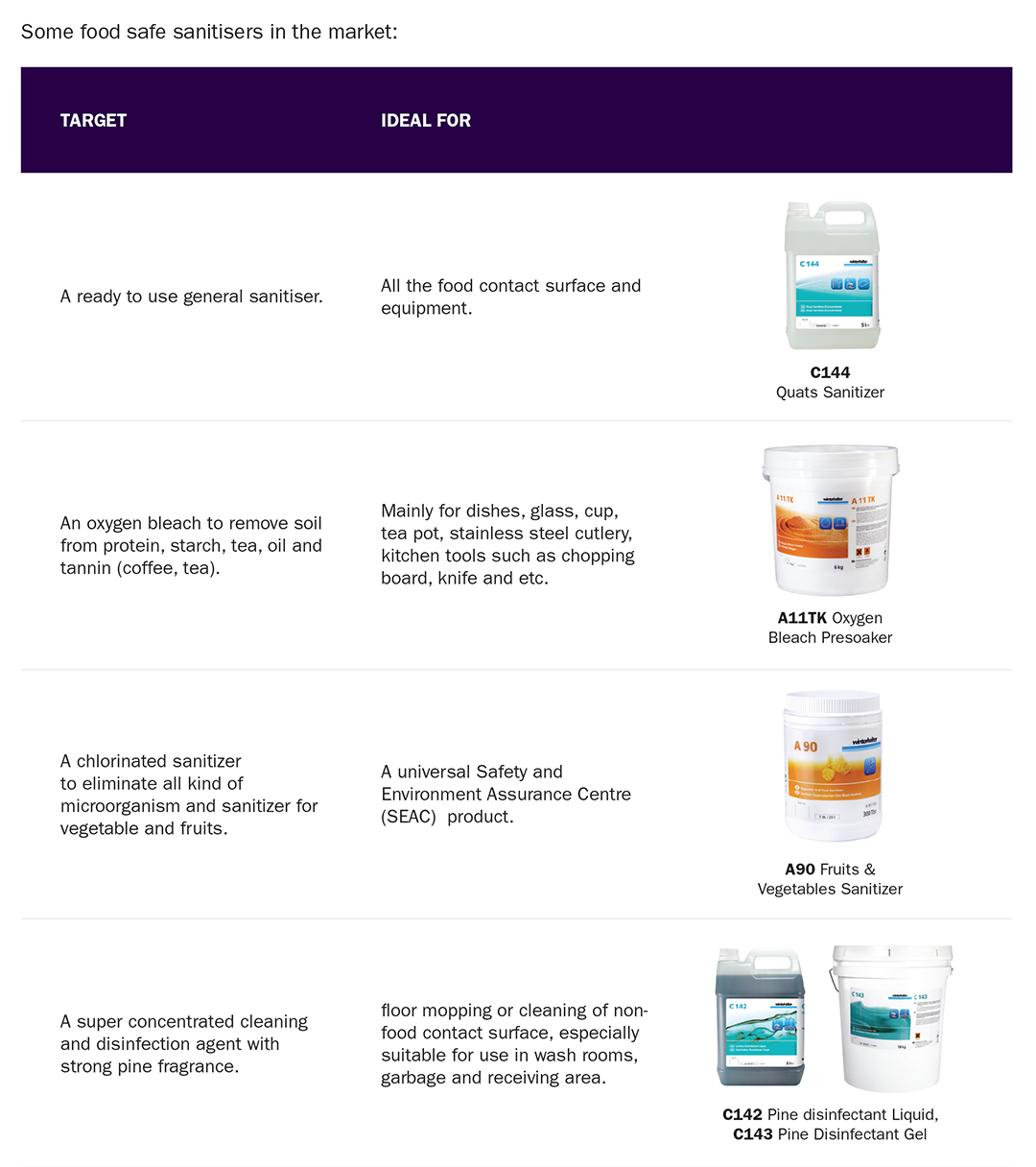

Tableware, utensils and equipment can be sanitised by soaking them in a chemical sanitising solution, or rinsing or spraying them with sanitising solution. Three common sanitiser are chlorine, iodine and quaternary ammonium compounds (quats) and these chemicals sanitisers are regulated by state and federal environmental protection agencies.

Winterhalter various sanitisers – C144, A11TK, A90, C142 & C143

And for all handwashing and cleaning to happen, there is one important element. Read on in our next article with T&S Brass & Bronze Works, Inc where the magic of good hand washing practices happens – the sink.

Our thanks for Winterhalter SEA for their time. We can only improve with information and it goes a long way to helping everyone beat the virus and come out on top.

href="#" data-color-override="false" data-hover-color-override="false" data-hover-text-color-override="#fff">Button Text