“When can I make back my investment?” A question every business person would ask when they start a new business or when they plan to expand their existing business. It is indeed a reasonable and wise question but is there a clear cut answer? Moreover in a business known as one with many successful determining factors; many still go in thinking they can recoup their investment or profit after the first 3 months. It is not surprising that many new operators look for the cheapest equipment in the market or something they categorise as affordable even though the equipment might not be meant to withstand commercial use. The idea of “use it first and when you star t making it, invest in a better one”usually sets the tone.

Sounds like a smart move as F&B’s mortality rate tend to be high. However, by using equipment inadequate to weather the constant abuse in a commercial kitchen; would you be setting yourself up for failure if the business does better than expected? Would you be able to produce consistently and quickly to serve your crowd? It is actually a ‘chicken or egg’ question but from our discussion with many business owners; the consensus is “How serious are you about making this happen?”Sounds like a no-brainer question right? However, many are actually investing in the industry as a hobby, just to put extra money somewhere or even the pride of saying “come to my cafe!” Well, if you fall within these categories, continue buying what you fancy but if you are in the game for the long run, it might be smart to hit the books and run through the figures again – to find a closest possible answer to picking the right equipment to start and how to calculate your returns.

Sounds like a smart move as F&B’s mortality rate tend to be high. However, by using equipment inadequate to weather the constant abuse in a commercial kitchen; would you be setting yourself up for failure if the business does better than expected? Would you be able to produce consistently and quickly to serve your crowd? It is actually a ‘chicken or egg’ question but from our discussion with many business owners; the consensus is “How serious are you about making this happen?”Sounds like a no-brainer question right? However, many are actually investing in the industry as a hobby, just to put extra money somewhere or even the pride of saying “come to my cafe!” Well, if you fall within these categories, continue buying what you fancy but if you are in the game for the long run, it might be smart to hit the books and run through the figures again – to find a closest possible answer to picking the right equipment to start and how to calculate your returns.

We had the pleasure of visiting a modern kitchen where its modest and simple setup hides a commercial kitchen fitted with equipment that you might not even see in some bigger establishments. Tucked away in a golf resort in Bangi, a district south of Kuala Lumpur; Bangi Golf Resor t‘s (BGR) kitchen is fitted with the industry’s top liners. Its operator attributes technology in equipment to its success in maintaining quality, consistency and impressive food costs.

We had the pleasure of visiting a modern kitchen where its modest and simple setup hides a commercial kitchen fitted with equipment that you might not even see in some bigger establishments. Tucked away in a golf resort in Bangi, a district south of Kuala Lumpur; Bangi Golf Resor t‘s (BGR) kitchen is fitted with the industry’s top liners. Its operator attributes technology in equipment to its success in maintaining quality, consistency and impressive food costs.

We sat down with Mr Soh Chung-Ky to understand how he and his team serve up to 2000 per event and yet no one is rushing, shouting, looking tired or seem disgruntled as what is often portrayed in commercial kitchens. In fact during our visit, some of his 16 member strong team was having a R&D session with a potential new “toy” that the management might be looking to add to their already impressive lineup of equipment. Despite not having a chef’s title to his name, how did all this come together? Did his background in mechanical engineering play a role?

We sat down with Mr Soh Chung-Ky to understand how he and his team serve up to 2000 per event and yet no one is rushing, shouting, looking tired or seem disgruntled as what is often portrayed in commercial kitchens. In fact during our visit, some of his 16 member strong team was having a R&D session with a potential new “toy” that the management might be looking to add to their already impressive lineup of equipment. Despite not having a chef’s title to his name, how did all this come together? Did his background in mechanical engineering play a role?

Well, the answer is Research and Development. To Chung-Ky, his first rule is “cook it right”. It simply means, before you can really invest in an equipment or think about expansion – cook it right first. Make sure your recipe works for you and that your customers genuinely like your product. Gather feedback and engage in a repetitive cooking, testing and feedback process until you get it right. Next, improve your cooking processes, document your recipe and simplify any complicating procedures that may be unnecessary. Finally, implement a rigid cooking process that is well documented for the menu items that you can sell confidently. Only after that can you explore other advanced cooking methods such as ‘Cook-Chill’ and ‘Sous Vide cooking’. He has a list of guidelines in choosing an equipment:

Well, the answer is Research and Development. To Chung-Ky, his first rule is “cook it right”. It simply means, before you can really invest in an equipment or think about expansion – cook it right first. Make sure your recipe works for you and that your customers genuinely like your product. Gather feedback and engage in a repetitive cooking, testing and feedback process until you get it right. Next, improve your cooking processes, document your recipe and simplify any complicating procedures that may be unnecessary. Finally, implement a rigid cooking process that is well documented for the menu items that you can sell confidently. Only after that can you explore other advanced cooking methods such as ‘Cook-Chill’ and ‘Sous Vide cooking’. He has a list of guidelines in choosing an equipment:

• What process can it replace in the kitchen?

• Can this equipment reduce the process time?

• Can it do with minimal human super vision? Can I free my staff to work on other things?

• Can it reduce human fatigue? Will it help to mitigate human errors?

• Will it increase my yield per portion or reduce my wastage?

• What is its efficiency over a period of time – maintenance, parts, repairs and service?

• And at the end – What is the amount of money I can save from investing in this particular equipment

For example:

PROCESS 1

2 staff

4 hours daily

Wastage – 5%

Output – 50kg

Wear & tear of tools

PROCESS 1 with equipment

2 staff

1 .5 hours

Wastages – 2%

Output – 65kg

1 equipment (Your asset)

Put a figure to ever y item above and multiple it by 365 days, you would be surprised by what you are able to save. That savings would enable you to cover your cost of purchase plus additional operating cost. In some cases, Chung-Ky has mentioned that he recovered his investment in less than 2 years.

Having said that, he doesn’t believe you should jump in and buy everything at the same time but advises that you choose wisely and approach it one equipment at a time. It is important that you are very clear on your processes and identify if purchasing an equipment to reduce that particular process is going to make an impact. Make the equipment work for you as many are designed to operate overnight, use that as you are already paying rental around the clock!

His comment that “I rather not be fire fighting everyday!”makes the investment on equipment and time spent for creating simplified and documented processes all the more sensible as you are able to navigate around the all too often heard complaint about high staff turnovers and food not being presented consistently.

“I have been very fortunate to work with many professional manufacturers and their consultants who gave me great advice and help. Get them to help you, visit them, talk to others in the business, tell them the issues that you are facing and you would be surprised that they might already have a solution”.Implementing technology and equipment has played a pivotal role in the development of Bangi Golf Resort’s foodservice business.

However, as every business is not the same size nor do they have the same menu, there is no sure formula. Thus, together with our partners and manufacturers, we attempted to do a simple calculation. Depending on the size, location, concept, décor and type of service, there was still too much for us to work through to come up with a standard list. But our partners have helped us to identify some areas that would be your higher investment and how you should evaluate them.

IN THE KITCHEN: COOKING WITH COMBINATION OVENS

IN THE KITCHEN: COOKING WITH COMBINATION OVENS

Where there used to be 6-7 equipment in a row, today’s equipment are smaller in footprint, uses less energy and packed with features to provide a better user experience. Like Combination ovens for example – it can grill, steam, panfry, bake, proof, roast, braise, simmer, stew, poach or blanche.

Previously, you might need 4-5 people on 4 – 5 equipment to work in the kitchen, now you could do with 2-3 staff with less equipment and make the oven work overnight with its overnight cooking feature. Most combis are fitted with this function and this would help you to free up time during the day and also reduce the number of staff in-house.

For RATIONAL, the company has also taken a conscious effort to ensure that its SelfCookingCenter® units have earned the ENERGY STAR.

Compared to standard equipment, ENERGY STAR certified combination ovens on average are roughly 30% more efficient. This means that they have an estimated annual savings of $250 (gas models) and $700 (electric models), save roughly 28 MBTU per year or 7,121 kWh per year and have a lifetime savings of $2,500 (gas models) and $6,800 (electric models), which is based on a 12-year lifespan and 4 percent discount, and actual savings will vary depending on use. For more information about the ENERGY STAR program for commercial ovens, you can visit their website at: https://www.energystar.gov/certifiedproducts/detail/commercial_ovens.

![]()

Get a RATIONAL agent to show you how to start saving at www.rational-online.com

YOUR ENVIRONMENT: HVAC – HEATING, VENTILATION, AIR CONDITIONING

This is one section where many operators would try to cut back or take a simpler approach but it drains you in ways that you might not be aware of. In Asia, HVAC relies heavily on electricity from your air conditioners to your exhaust systems. Together with kitchen equipment, 80% of a restaurant’s energy consumption is used to just serve and keep the environment comfortable for your patrons and your staff.

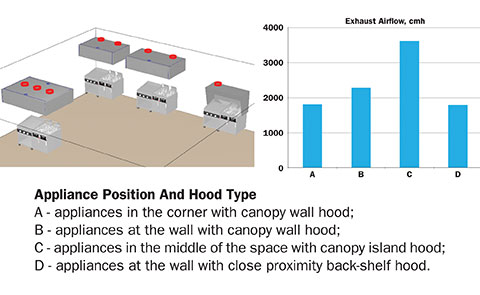

However, common mistakes or miscalculation causes many operators to pay for even more energy than what they could have saved EVERYDAY. Mistakes such as treating your dining room and back of the house as 2 separate spaces with independent ventilation systems or relying on air from outside the mall. And even the design of your kitchen workflow affects your exhaust airflow as shared by HALTON.

Smart practices of minimising exhaust airflow will save your fan’s motor energy during extraction while reducing energy consumption to replace the air that is being extracted. Professional HVAC systems such as HALTON have proven their worth and big establishments implement them confidently even with big show kitchens right in the middle of the dining area. Optimisation and reduction of utility costs will enable significant savings for operators. And on top of that, reduce the discomfort of patrons walking out smelling like their meal.

Smart practices of minimising exhaust airflow will save your fan’s motor energy during extraction while reducing energy consumption to replace the air that is being extracted. Professional HVAC systems such as HALTON have proven their worth and big establishments implement them confidently even with big show kitchens right in the middle of the dining area. Optimisation and reduction of utility costs will enable significant savings for operators. And on top of that, reduce the discomfort of patrons walking out smelling like their meal.

![]()

Speak to HALTON at www.halton.com

IN THE KITCHEN: DEEP FRYING

IN THE KITCHEN: DEEP FRYING

Deep fryers need oil, lots of oil. Older tanks in deep fryers were deep and was a hassle as it required constant filtering to lengthen oil’s life in the tank. The hot oil is not easy to handle and it is disposed after a certain period to ensure freshness. Despite the procedures, it remains on the list of equipment due to the love many have for fried crispy food. When we talk about the return on your investment, the equipment has to be able to save you something somewhere. FRYMASTER has just recently launched its new range of fryers for the purpose of helping businesses “conserve”.

The OCF30 Fryers has a smaller tank and is able to perform with 40% less oil to compared to its 50 lb. competitors. Less oil used, less wastage. Its new FILTERQUICK® feature will help the operator conserve the oil in the tank. It has a fully automated filtration system that helps you to manage and protect the oil in the tank, maximising oil life up to 4 weeks or more. Regular filtration can be carried out with a simple push of a button. It has an oil quality sensor that measures oil contaminants and lets the operator know when it is time to change the oil and has sensors to detect low oil levels while automatic top-up kicks into place.

The new OCF range of fr yers will be coming soon into Asia. Contact Frymaster at www.frymaster.com

![]()

A commercial kitchen requires equipment but many times owners are uninformed of what they really need. We could go on and on about the equipment but we hope these insights would give you a clearer idea on evaluating what to buy, when to buy and how to use it to your advantage. Too many establishments leave equipment unused and wasted because they were never maintained yet were still exposed to the harsh environment of a kitchen. It is not about how much money you have to throw out and buy machines but it is about drawing a blueprint for the equipment you plan to get and how will it benefit your current process chain. And although some may cost more but you are definitely doing business with the long run in mind, thus these machines are built to help operators to save time and money in due course.