One of the most time-consuming and resource consuming task is undeniably dishwashing. Surely you might have encountered eating at an outlet with such high turnovers that cutlery or tableware are not washed quickly enough or even spotting debris left on the ware. And of course not everyone is like Pete Jordan, or popularly known as “Dishwasher Pete”, who once made washing dishes in

every state in America his goal. Restaurants, cafeterias, resorts, hospitals, a fish cannery, camps, communes, an offshore oil rig, a dinner train..just anywhere there were dirty dishes to be cleaned. Well, there aren’t thousands of Dishwasher Petes out there so machinery would be the only answer.

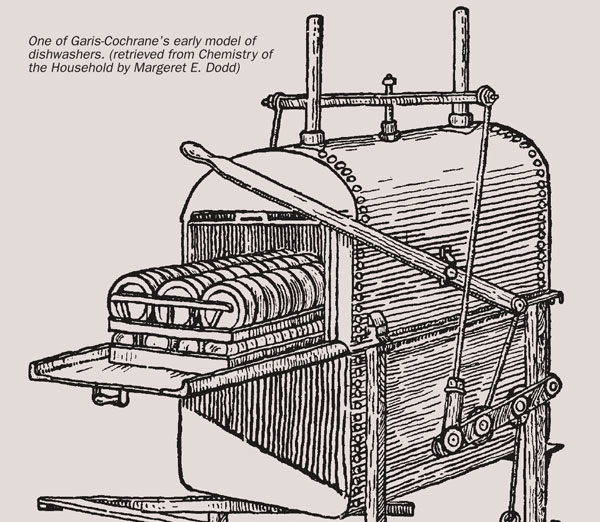

Warewashers was first made by Joel Houghton in 1850 and although given a patent, his crude hand-turned splashing device attached to a wooden tub did not fly. LA Alexander added gears to a spinning rack to hold dishes, which could then be spun inside a wooden tub of water. It was not any better either; until Josephine Cochrane introduced hers in 1886. She built a contraption of a wooden wheel that lied flat in a copper boiler and the wheel was turned by hand or driven by a power source via a pulley while wireframed compartments held the dishes to be washed. It was a revelation to hotel and restaurant owners then and Cochrane’s dishwasher went into mass production which is now today the world famous KitchenAid company.

Today, dishwashers come in various sizes and no matter how large or small your establishment is, there will be an option for your needs. Below are the types of dishwashers in the market:

RACK-TYPE

A vertical installation, wash wares are loaded into racks and put through the machine from the side. After washing and rinsing, racks are discharged through the same side at the exit end of the dishwasher. Suitable to be installed in spaces of narrow ends with the soiled dish table and clean dish table in parallel with the washing mechanism unit.

UNDERCOUNTERS

A smaller unit that will fit below the counters, especially in bars or smaller kitchens. Operators can clean small batches or up to 20-30 racks of glasses and dishes at one time although not as quickly as a hood version. It is suitable if you need a steady supply of clean dinner ware throughout service and have minimal space for a larger unit. Undercounters look like residential washing units with its single door upfront but are definitely more comprehensive in its washing modes and productive in its work.

CONVEYOR

The second largest type of dishwasher is capable of washing hundreds of racks in an hour and is used in kitchens that serve up to 1,500 meals at one time such as institutions, mass catering or banquet kitchens. A conveyor can be built with up to 3 tanks for wash, rinse and sanitising cycle respectively with most using hot water sanitation although units working with chemical sanitation and lower temperatures are available. Conveyors are usually custom-designed and one of the most important factors is specifying the travel directions of dirty and clean dishes; whether left-to-right or right-to-left as the units are difficult to reposition once in place, not to mention a hassle to redesign the entire dishwashing area.

POT WASHERS

Pots, gastronorm pans or other unusually sized crockery do not fit into dishwashers and stewards usually wash them by hand. The task would require overnight soaking and hard scrubbing which takes up time and resources. Pot and pan dishwashers are designed for large sized items and comes with high-pressure wash systems to get rid of stubborn food residue in lesser number of cycles. This also means the units need higher voltage to support its operation thus it is important to check the electrical system’s capacity before committing to a unit.

FLIGHT-TYPE DISHWASHERS

Custom-built and able to handle up to 14,000 dishes per hour, flight dishwashers work like a conveyor but dishes are placed directly onto a moving belt without a rack. It is the preferred choice for large establishments like hotels and resorts, universities, correction facilities, banquet halls and hospitals.

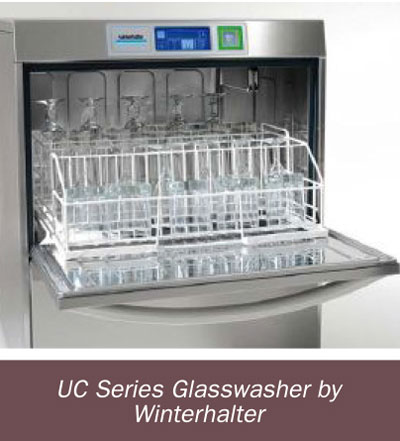

GLASSWASHERS

Typically found in bars, these units are designed with a lower water pressure to prevent breakage of delicate glasses. These can be fashioned as an undercounter door-type, passthrough conveyor style, and carousel types. The carousel runs with a spinning conveyor and is separated by metal or plastic dividers with 3 compartments – one to place dirty glasses, the second is the wash compartment and thirdly, the sanitation area. A carousel glasswasher can prove convenient for loading and unloading glasses at any point during the washing and sanitising process.

Zooming into…hood-type dishwashers

The tank is filled with fresh, clean water at the start of the cycle and the water is discarded when the wash is complete. This would have been considered wasting resources but technology has made it possible for the machine to recycle the wash water. The stand-alone machine comes with a tall door with 3 connecting sides which can be pulled down to close after dishes are loaded. It is considered the most widely used type of dishwasher especially for restaurants that serve 300 – 1,500 covers a day and machines can clean between 50 – 125 dish racks per hour, depending on model. Given that it is the most widely used dishwasher type, we have prepared a special feature on the hood type dishwasher as it is the type most suitable for restaurant operations. By listing down the main categories and its features, you can make comparisons and have an idea of what you are looking for before speaking to the professionals.

* Mise En Place does not endorse one brand over another and features are stated as they are.