As we read articles and news repeatedly reported on high real estate costs or insufficient skilled manpower for the service sector, its impact would not escape those in the F & B industry. And a solution have always been there – offered in my trusty old text book – The Theory Of Catering by Ronald Kinton and Victor Ceserani.

As we read articles and news repeatedly reported on high real estate costs or insufficient skilled manpower for the service sector, its impact would not escape those in the F & B industry. And a solution have always been there – offered in my trusty old text book – The Theory Of Catering by Ronald Kinton and Victor Ceserani.

In the textbook, problems such as limited skilled staff, high food cost and wastage, equipment costs and maintenance and even space constraints were identified possibly since 1964. And the solution offered comes in the form of centralised kitchens.

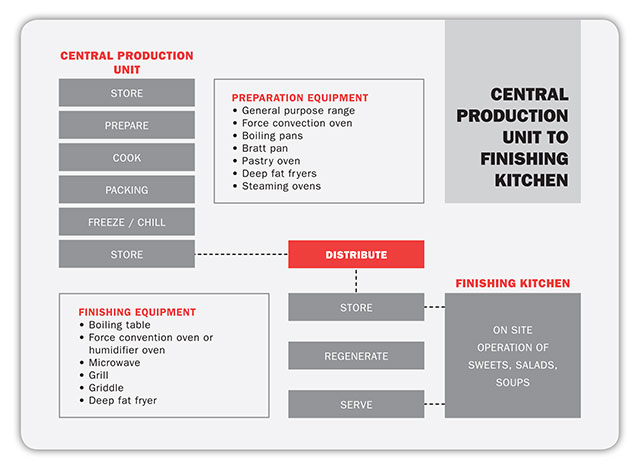

To explain – centralisation kitchen production means using skilled staff to prepare and cook in bulk and then to distribute to finishing kitchen, which are smaller in size, employing semi-skilled and unskilled labour.

Of course, centralised kitchen are normally practiced for establishments that operate in more than 1 location like chain restaurants or establishments that serves a large volume in a short period of time such as banquets or hospitals. When practising centralised production, common issues below can be better managed:.

• Labour – skilled labours are required only at the central kitchen. Outlets can be maintained by semi skilled labours that can lower operational costs,

• Food costs – on top of competitive purchasing through bulk buying, the wastage can be reduced as only 1 location would be involved in preparation,

• Equipment costs – investing in one location for heavier equipment instead of numerous locations,

• Product quality – the taste and quality of food is standard throughout.

3 cooking methods were developed and each has its own advantages over the other, depending on the size and nature of your restaurant.

COOK CHILL SYSTEM

COOK CHILL SYSTEM

Cook chill is a system based on normal preparation and cooking of food followed by rapid chilling then stored in controlled low-temperature conditions above freezing point, 0°C to 3°C (32°F to 37°F). Food is then subsequently reheated immediately before consumption. The chilled food is regenerated in finishing kitchens that require low capital investment and minimum staff.

COOK FREEZE SYSTEM

Blast freezers have increasingly been introduced with success into catering operations. The ability to freeze cooked dishes and prepared foods, as distinct from the storage of chilled foods in a refrigerator or already frozen commodities in a deep freeze, allows a caterer to make more productive use of kitchen staff. It also enables economies to be introduced into the staffing of dining rooms and restaurants.

SOUS VIDE

SOUS VIDE

This is a form of cook-chill: a combination of vacuum sealing in plastic pouches, cooking by steam and then rapidly cooling and chilling. The objective is to rationalise kitchen procedures without having a detrimental effect on the quality of individual dishes.

Cook chill requires less time to regenerate when compared to cook freeze and the need to thaw foods are eliminated. But cook freeze allows better purchasing power as purchase is done to cover more calendar days and frequency of delivery can be reduced. Meanwhile sous vide cooking has an even longer shelf life but would incur additional costs for vacuum pouches and packing machines.

When opting for a centralised kitchen format, besides identifying the necessary process, you need to also work out the details for the points below to ensure that your centralised kitchen concept can operate smoothly.

A. The regeneration process or finishing kitchen – the final stop. This depends on the establishment’s service mode. Restaurants would use a finishing kitchen where as hospitals distributes chilled meals into specially designed trolleys/ovens, which has built in thermal heating system. Finishing kitchens are equipped with regeneration equipment such as combi ovens, microwaves or rethermalisers. In addition, equipment to prepare accompaniments and refrigeration for storage should be considered as well.

B. The distribution and transportation – fluctuations in temperature can affect the palatability and texture of food. The chosen mode of transport must ensure that the required temperature is maintained consistently throughout transport.

C. The containers and storage used-re-usable containers of metal or ceramic are used. Note that the depth of the food containers must be carefully controlled to ensure even and complete heating in the finishing cycle. If food is portioned out, disposables are normally preferred. The graph would best show how a central production kitchen prepares and distributes to the finishing kitchen with the variety of equipment used listed.

However, note that planning and forecast plays a very important role in ensuring the success of your centralised kitchen as well. Though preparation is done collectively at once and wastages are reduced, if there should be a miscalculation in production volume, to organise a small batch production might incur higher cost and building up of stock as both raw and cooked produce would lead to loss on both ends.

However, note that planning and forecast plays a very important role in ensuring the success of your centralised kitchen as well. Though preparation is done collectively at once and wastages are reduced, if there should be a miscalculation in production volume, to organise a small batch production might incur higher cost and building up of stock as both raw and cooked produce would lead to loss on both ends.

Source: The Theory Of Catering – 6th Edition (1989) by Ronald Kinton & Victor Ceserani.