Did you know “Fried food” is essentially “deep fat frying”? Even back in the 1930s, society had its reservations and industry players tried to avoid using the word ‘fat’, simply calling it “frying”. Psychology games? Well, this is not a debate on fried food but a focus on the technology of frying from Frymaster. While the home chef can get along with deep frying in the same vessel he uses to cook any other item, it required a different enginering perspective altogether for high volumes. And this perspective was ignited in Peary Foster Ratcliff around 1935.

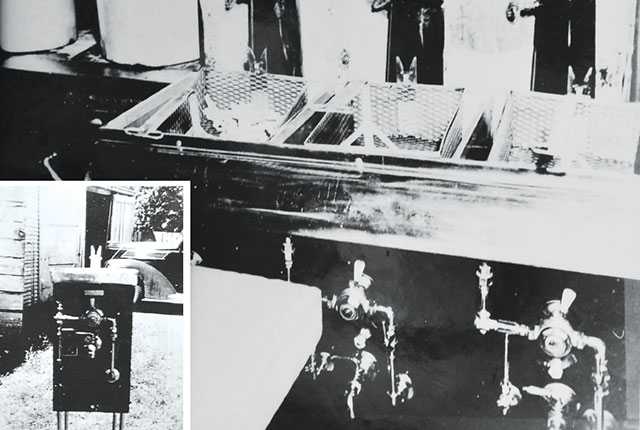

The first Ratcliff Frymaster unit

Simplicity of operations

For a man with only a 4th grade education, he possessed a mechanical talent and was known around town as the man who could fix almost anything. His two-car garage in Shreveport, Louisiana was a place he spent a lot of time tinkering and birthed the first Frymaster deep fryer based on the idea of an open frypot and master jet burner which removed the need for visible heat exchangers that usually made cleaning the frypot a difficult task. Many tweaks later, the Frymaster jet burner was introduced and was the leading innovation for thousands of its gas fryers in years to come.

P.F Ratcliff at a product demonstration

Frymaster bakery equipment

CARVING ITS NICHE

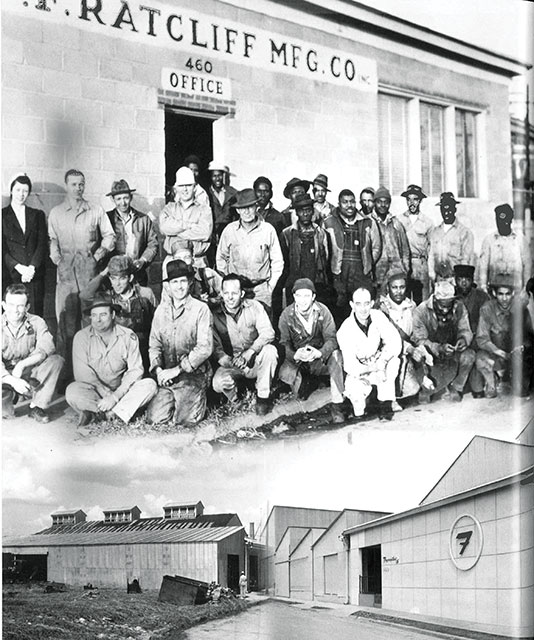

Like many small enterprises of that time, Frymaster began on a slow route and also went through the war. Postwar in 1945, America was still reeling from the effects and employee availability was scarce yet Ratcliff managed to gather enough to complete its 5,000sqft plant. It was a time of thinking out of the norm and giving cutomers their wishes; even if it meant constructing sixteen gas fryers in one unit. As there was no standard value to architectural design fees, very often the company made less than what it would have cost for customisation today. Determined to make the best out of the lean times, the Company took old fryers and rebuilt them although it took them more time but it was good for customers’ affordability. If pastry goods needed deep frying, why not make one? Working with a Bruce Jones, Ratcliff designed not only fryers for doughnuts but equipment for an entire doughnut production.

TECHNOLOGIES FROM FRYMASTER

Another issue that faced frypots was breading and crumbs will eventually fall downwards thus burning and clogging the drainage. Ratcliff saw that its better to keep those crumbs below the heated area as the fat was 150°F cooler below the burner area. As a measure to reduce the use of fat, he reduced the cross-sectional area between the cold zone and frying area while a second high drain above the crumbs was later added to rapidly drain off the clear oil.

Eventually, Ratcliff retired and sold the business to L. Frank Moore, Hershel H. Herring and Robert L. Dunkelman. The new owners changed the way products were made and marketed. In reducing scrap volume, cutout standards were developed for frypot parts followed by purchasing for stainless steel sheet blanks cut to exact sizes. The company began to flourish and earned design certification on its standard models from the American Gas Association.

Crisp perfection

From open-pot design and patented fryer jet burners, the team built a 10°F action thermostat and equipped it with built-in filtration and computer controls. Fryers became more efficient with infrared burners and fully-controlled programmable cooking that automatically adjusts cooking time and temperature, filters out waste and shuts down. This factor proved to be a selling point for giant food chains as it guaranteed uniformity in taste across regions.

The 460 Fortson Street site

Frymaster planned a system that would be able to employ computer-assisted automation utilising bar codes and radio frequency data communications (RF/DC) in streamlining operations alongside tracking and validating business orders and inventories. Bar code scanners and RF/DC terminals were introduced to keep track of both inventories and work-in-progress, speeding both the handling and shipping of buyers’ orders.

In 1967, it introduced the automatic basket lifter to complement the electrical timers so that foods are removed at a precise time. The FootPrint model housed a filter and fryer in the same cabinet and it has progressed to computer controlled frying with automatic basket lifters and built-in fat filtration in single or multiple units. This allows operators to filter the oil several times a day to extend the fat life and improve quality of foods fried.

Around the mid 1970s, electric fryers were introduced as the company saw chain restaurants using both gas and electric fryers. The 12EF, 17EF and 22EF models featured swing-up flat-sided elements that combined excellent heat transfer surfaces with narrow tops in minimising burning crumbs. As cold zones were incorporated, temperature control had accuracy. Frying computers were designed with microprocessor chips and a team was set up to research how to control cooking times for a wider variety of loads and find the baseline of getting consistent results regardless of starting temperatures or quantity fried. It was a success and continues to be a standing feature in Frymaster products. Even Frymaster users were innovative. One restaurateur tried using his fryer to boil shrimp and crawfish but it rusted badly. Instead of pointing the customer to another manufacturer, the customer got a unit with non-rusting components. With that insight, the team found a way to develop an automatic pasta cooker. Over the years, it manufactured other products like the microwave oven (a decision by Sunbeam who had acquired Frymaster then) and the tilting fry pan which did not quite make it. Well, back to what it knew best?

Frymaster at work

GETTING THE WORD OUT

Not shying from competition, Frymaster did a short film entitled You Be The Judge that showcased the difference of a unique cold zone in Frymaster compared to a competitor’s unit. Road shows were also important as it was the most plausible avenue to reach the most potential customers in the least amount of time. Not forgetting ongoing healthy work relationship with its dealers; this is a story of how Kentucky Fried Chicken (KFC) signed on.

L. Frank Moore at Groundbreaking ceremony for Manufacturing Addition (top)

and President David Mosteller receiving Presidential E Award

In the 1950s, a dealer named Leon Rees sat next to Colonel Sanders during a dinner and instead of rehashing facts and figures, he built a visual image of how it could help the business and that immediately got the Colonel to visit the Frymaster exhibit and promptly signed on! In addition, KFC had products designed exclusively for them like the KFC Hot Shortening Unit and KFC Portable Speed Table.

As the industry began to see the benefits of specific frying equipment, Frymaster’s visibility grew and needed a bigger space. The move in 1965 to Hollywood Avenue had a space doubled Fortson St. and was enlarged twice to reach 96,000 sqft before moving to its 22-acre site in the 1980s; remaining till today. In the next decade, it would have enlarged its plant to a total of 400,000 sqft in separate periods, and boosted its workforce to about 400-plus personnel.

The company’s strive for top notch quality fryers did not go unnoticed as it won the “E Star” award given by the U.S. Department of Commerce for excellence in exporting and Frymaster’s products also met the five ISO 9000 standards for quality assurance; a virtual must for companies doing business in Europe.

After a few acquisitions and mergers over the years, Frymaster is now under the Manitowoc Foodservice banner. The holding company hosts comprehensive online advertising campaigns for dealers, distributors, foodservice consultants, industry associations and end-users to utilise. Monthly e-newsletters go out to over its 15,000 and more business associates while product websites and mobile sites are constantly updated.

Frymaster’s targeted solutions are in line with the entire vision where Manitowoc strives to identify optimum solutions for targeted demands; in short to “excite, entice and enable foodservice operators, to do more with less”. Here’s closing with the sentiment that the lure of fried foods is here to stay and that Frymaster knows it to be true; tracking innovations since 1935.

Inquiry.MFA@manitowoc.com

www.manitowocfoodservice.com