It is something you have always known – commercial kitchens are energy guzzlers. Yet you cannot run without machines. With that in mind, manufacturers have taken steps to provide you with choices to be a more eco-conscious kitchen.

Food For Thought?If food waste were a country, it would be the third largest producer of greenhouse gases in the world, after China and the U.S! (United Nations.)

Waste management > MEIKO Wastestar CC

About 30% of global food production end up in landfills and undeniably much coming from food facilities. The WasteStar CC is an independent unit where users simply tip the food waste and organic leftovers into the unit. Its built-in high powered grinder and crusher breaks down everything including hard items like bones, shells and crustacean exoskeletons. The resulting homogeneous biomass becomes a valuable substrate which is a key energy source – 1m³ of substrate can produce some 60m³ of methane. That’s about 60 litres of heating oil or diesel equivalent; able to fuel a car for some 850 kilometres.

The collected substrate mixture will be periodically pumped into a separate collection tank to be collected by tank trucks to bring it to biogas, composting or sewage plants thereby creating a running recycling loop. It is also possible for the unit to be connected directly to a composting or digesting unit. Incorporating this waste management method cuts out the occurrence of unpleasant rotting food odours that attract flies and vermin to the kitchen. It also saves space and footwork when staff do not have to move open buckets containing food waste to another location for disposal. One Wastestar CC unit is able to handle food waste of up to 180kg an hour; equivalent of 900 meals. The unit is suitable for smaller establishments like cafe and bistros to larger facilities like hospitals and catering kitchens, as a complete system.

Stay In Ice!Ice hotels have been quite a phenomenon inside the Arctic Circle. Ever ything is made of ice but you do get to sleep in polar-rated sleeping bags.

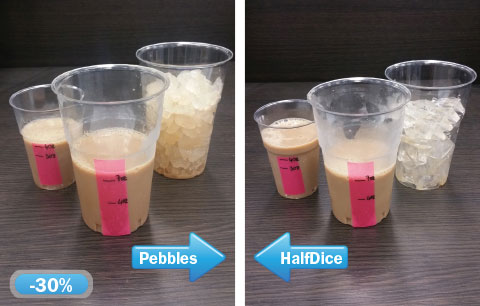

Comparison between two ices after 20 minutes: Half Dice releases 6 Oz on top of the original 7 Oz (+86%) Pebbles releases 4 Oz, on top of original 7 Oz (+57 %)

For The Cold > Brema Pebbles System Technology

Ever thought of your water footprint when scooping up ice from ice machines into drinks? A typical CUBED ice maker would use 2 to 4 litres of water to produce 1kg of ice. With Brema’s introduction of its Pebbles System, users can have 1kg of ice using only 1Litre of water. By combining the action of an auger and extruder, continuous production in a stable cycle is possible; resulting in low operating costs and high efficiency in production. Pebble ice or “micro-cube”as Brema coins it, is a meeting point between fast-ice and classic flake ice that has a fast cooling ability making it suitable for cocktails, seafood and buffet presentation. With a 92% dryness, it gives users more ice per production cycle and ice are also less likely to stick together. Here’s an example to calculate water footprint:Sample: Italian establishment with 10 outlets

Ice usage: 100 kg of CUBED ice per outlet per day

Water to make ice: 2800 litres (total)

26 working days = 72,800 per cubic metre x 2,2 Euro (MC) = 160, 16 Euro

160, 16 Euro x 12 months = 1922 Euro / year

Using Pebble Ice: annual water cost 468 Euro

Savings per year – 1454 Euro

Its ice’s low diluting effect allows operators to use less ice in a cup and ensures a drink doesn’t become tasteless too fast.

Did You Know?About 400 pieces of fried chicken are sold per minute by KFC in United Kingdom.Just imagine the deep fryers working there and around the world!

Hot Cooking >Frymaster Oil Conserving Family of Fryers (OCF)

Hot Cooking >Frymaster Oil Conserving Family of Fryers (OCF)

Deep-fried food uses plenty energy – power to heat up a deep pot of oil, the high flame to cook and management of used oil. When to change the oil is a regular dilemma as people used to tell oil quality just by looking. Frymaster’s eliminates the problem and is the first manufacturer to introduce the Oil Quality Sensor (OQS) in its range of OCF. The integrated sensors fitted in the deep-fr yer measures the state of degradation of cooking oil or fat. OCF models exceed ENERGY STAR guidelines therefore using one will allow operators to qualify for energy saving rebates**. Complementing the OQS function is the Auto Filtration (AF) that star ts easily and gets the filter pump agitating in the frypot before draining to lift the crumbs from the bottom of the frypot. Meanwhile Auto Top Off (ATO) senses the oil level and adds oil as needed from an in-cabinet oil supply.

OCF30

OCF30

®

The lean and green deep fr yer has a built-in Footprint Pro®filter together with a high fresh-to-used oil ratio. It offers oil life extension by up to 92%, reducing frequencies of refilling oil. A higher ratio of fresh oil also helps slow down the accumulation of foods’ by-products that typically compromises the quality of oil. A smaller tank of 30lbs means it is able to per form with 40% less oil compared to competitors in the 50lb range; yet yields 66% more food – less wastage and a lighter impact on the environment. A built-in filtration system enhances oil life preservation with a simple 2-lever process that incorporates recessed handles tucked safely inside the cabinet to prevent unplanned filtration and dangerous extension into busy work spaces. The main function of its SMART4U® OCF30 3000 Controller is to guide the user through each step of operation and maintenance. It also monitors and reports on oil level, oil life, cook counts, and fr yer performance while COOL mode holds the oil at a lower temperature during idle periods.

Surprise?200 households in Germany, Italy, Sweden and Britain with a dishwasher used on average 50pc less water and 28pc less energy than the households that didn’t own a dishwasher.

Cleaning with conscience > Winterhalter Green Chemicals

Most agree automating dishwashing is the way for ward. To achieve a comprehensive solution in dishwashing, users can practice green chemistry where chemical engineering focuses on designing products (and processes) that minimise the use and generation of hazardous substances. Winterhalter’s latest TurboZyme is optimised for the UF Series utensil washers and eliminates pre-washing. Using an enzymatic “crust cracker”and a special soaking program, dried and stubborn residues are loosened before the start of the actual wash cycle. The TurboZyme liquid is pH neutral, chlorine-free, phosphate-free and therefore belongs to the Green Chemistry category. This green “crust cracker” comes in 3 variants – the A100e for removing tough food residues, the A120e for starchy residues and A140e targets protein residues.

It also has chemicals certified with EU Ecolabel such as the F 720 BLUe. EU Ecolabel identifies products with fewer impacts on the environment and health throughout its lifespan; as compared to similar products in its class. The F 720 BLUe is not caustic nor irritating, is pH neutral, waste water neutral and preserves the material of commercial dishwashers. Also, all organic ingredients contained in the Winterhalter chemical products correspond to the required values for complete biodegradability under the criteria of the OECD test 302B and those specified in the Detergents Directive (EC) 648/2004. Winterhalter also obtained NTA-freeand EDTA-freecer tification and was the first manufacturer to completely forgo the use of NTA (nitrilotriacetic acid) in all its chemicals since 2010 as it was suspected to be carcinogenic.