“The chef dug a deep hole in the ground, placed logs in, started the fire, layered tea leaves over then settled the lamb down finishing off the covering with more leaves and soil; and waited for 12 hours. Due to non-direct exposure to heat, the lamb was pale in colour and the chef cooked it over a barbeque pit for that golden brown hue and crisp skin”.

That was a summarised description of a television program that we caught recently showcasing traditional cooking methods that many of us might not be familiar with given the advent of technology where everything is a turn of the knob or push of a button. It spurred the thought on how far we have come in cooking; where the principles remained unchanged yet how we have become more efficient – from mise en place, cooking methods, all the way to the hygiene factor.

WOOD

One of man’s greatest discoveries would be finding out that wood is an excellent source of heat for cooking as the intense heat from glowing hot embers cooks food thoroughly. Meats cooked over an open fire come with a bonus of having smokey flavours of wood infused into it. Cooking with wood is a matter of skill as you need to know not to place food on open flames that will char and burn the food but cook it on glowing embers. Although phasing out, we can still find wood-fired ovens in traditionalist pizza outlets where the smoke is channeled through a correct ventilation system that meets safety regulations.

CHARCOAL

Archeological evidence points back to about 30,000 years where charcoal was produced from wood because it has a more steady burn, is hotter and produces less smoke and vapours than wood plus having more potential energy per ounce than raw wood. Wood is cooked for days in a low oxygen environment so that volatile compounds like water, methane, hydrogen and tar is burnt off. The burning has to be stopped before wood turns into ash and results in black lumps and powder; the charcoal that we know. Although not much used in modern kitchens, there are still eateries that use charcoal as its heat source; particularly in Asia and with cooking that is done outdoors. Perhaps cooking with charcoal is more tradition and experience while the difference in taste can be debatable.

LIQUEFIED PETROLEUM GAS (LPG)

Commonly referred to as ‘gas’, it is produced by being extracted from petroleum or natural gas streams that emerge from the ground. It is preferred due to its non- ground and water polluting elements. Gas leaves no soot which helps to keep the working environment clean and used in household stoves, gained favour over wood or charcoal stoves because of its ease of operation and maintenance.

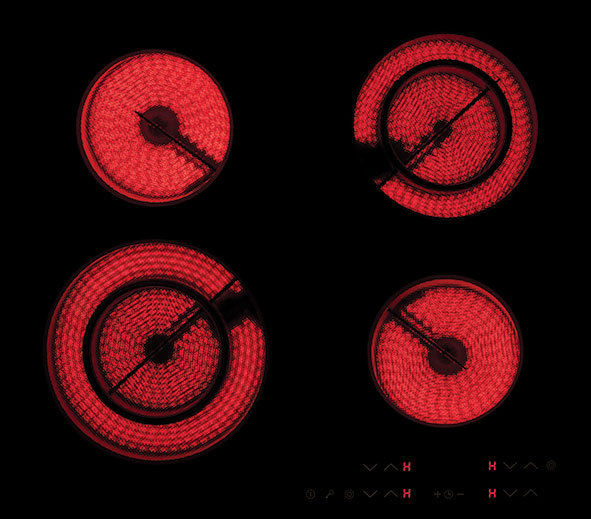

ELECTRIC

This discovery became a popular replacement for solid-fuel like wood or coal stoves because it converts electrical energy into heat for cooking. However, it did not take off well initially because it was unfamiliar and more electrical lines were required in towns to supply the power to use the stove.

INDUCTION

A coil of wire is mounted under a ferromagnetic cooking surface and as a large alternating current passes through it, a dynamic magnetic field is created to heat the pot or pan placed on the surface. Only the cooking vessel’s bottom is heated therefore reducing risk of burns. A minor limitation to inductive surfaces is the type of material cookware it can work with. Solid copper, aluminium, glass and ceramics should not be used on an induction stove but since it only involves the bottom surface, cookware manufactures are likely to coat that surface with induction compatible material and label it as such.

WASHING

Of course, everything was done by hand and pails of vegetables soaking in water were a common sight as workers rinsed and drained them dry in large baskets. It was a time consuming task that was especially tedious when it comes

to cleaning vegetables like spinach where soil tends to get trapped within the leave.

GRINDING / POUNDING

In Asian kitchens, a mortar and pestle made of granite is used to grind the ‘wet’ ingredients such as garlic, onions, chillies, ginger. It is usually shaped like a bowl and more suitable for lesser amounts while to grind larger volumes, a stone called ‘batu giling’ (Malay language) is used because the thick flat granite slab provides a wider surface for rolling down the ingredients. Without question, this method takes up a lot of time, energy and practice to do it fast as the juices from raw ingredients tend to sting your eyes. Although some purists might insist that the stone grinder imparts better flavours and more bite as the produce is not completely broken down; it is impractical to do so in a restaurant due to time and more importantly, hygiene.

CUTTING

The many cutting techniques a chef needs to master include dicing, slicing, julienne, chopping and in a range of sizes as well. Peeling skins of produce is also a time consuming task and people are hired specifically to peel onions and garlic which are supplied to food businesses; particularly high volume ones so that they can save time and labour from these tasks.

With the various heat sources as mentioned, more cooking techniques were developed and as mankind became more sophisticated, they sought to make their life easier with tools and created “a tool for each function”. A pan for stirfries, an oven for baking and roasting, a griddle for grilling, a deep-fryer for the crispy food or large pots for braising and boiling are just a few examples.

Imagine the array of appliances in one kitchen and if you talk to any senior chefs today about equipment, they will most likely name the combi-oven or combi-steamer one of the most revolutionary equipment because of its multi-cooking abilities housed in one. The first of its kind was introduced in the 1960s as a convection oven and a steam cooker in one that produces dry heat, moist heat or both at various temperatures. Because of the flexible heat source, chefs could cook almost anything with the advantage of short cooking times that has helped kitchens cook more food with lesser labour needs and though a unit may consume energy more than a regular oven, kitchens will save on the cost of running many types of equipment.

Having said that, there is still a need for single function equipment depending on nature of the food business, for example, deep-fried items that remain a favourite of many. Conventional deep fryers use a lot of oil which is a cost to consider because the oil should not be reused too many times. The early generation of deep fryers has different categories according to the type of food being fried. Lightly breaded food utilises open-pot fryers, tube type fryers for items coated in heavy batter while flat bottom fryers are used for specialty food or liquid battered cooking.

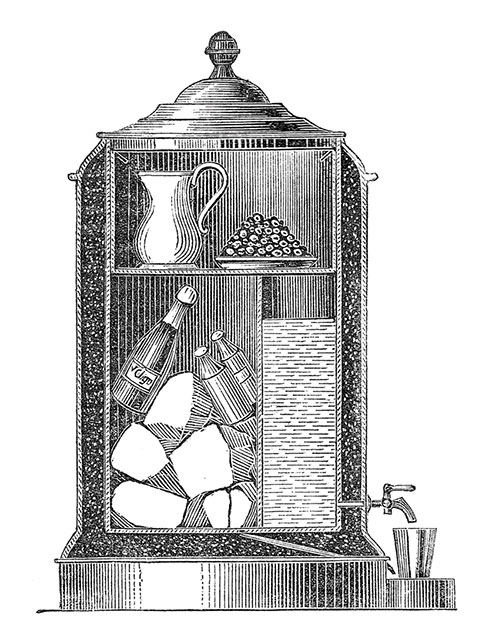

The Romans stored snow into storage pits, insulating it to be used as a cooling agent when required. In Egypt, people filled jars with boiled water and left them on the roof to be exposed to the night’s cold air. At the turn of the 18th century, the English learnt to collect ice during winter, packing them in salt and wrapping them in strips of flannel to be stored underground to remain frozen till summer.

For cool conditions of storage, people around the world also kept dairy items in cellars, in boxes kept outdoors or even underwater in nearby water sources.

Individuals like Dr. William Cullen, Michael Farady and Dr.John Goorie were instrumental in pioneering the technology of refrigeration. Their field of studies included evaporation of liquids in a vacuum, the process of liquefying ammonia to bring about cooling and the building of a machine to make ice to cool down yellow fever patients. Back then, it was not known as refrigeration, it was simply creating a cooling environment. The word ‘refrigerator’ was first used by Thomas Moore in 1800 although his creation looked more like an icebox. The timeline of this technology record that American Oliver Evans designed a refrigeration apparatus but Robert Perkins improved on it and got it patented in 1834. It was not until 1911 that the first officially recognised home refrigerator was made by General Electric which was designed by Marcel Audiffen. Until 1923’s self-contained refrigerators, the ice box had to be placed in one area while the mechanical parts installed separately.

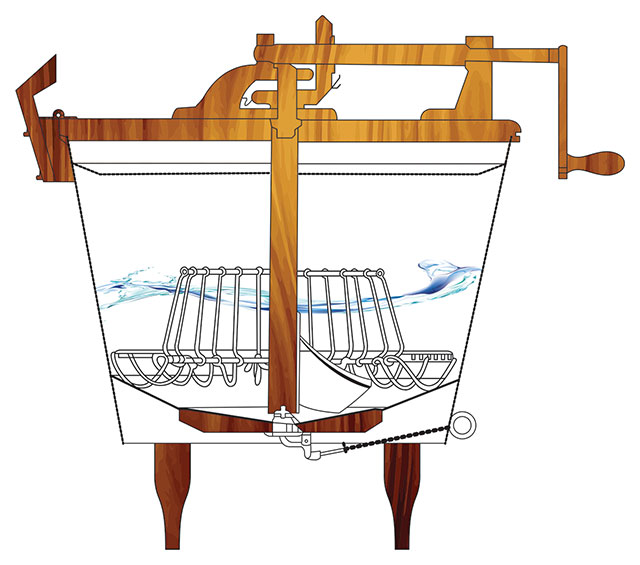

CLEANING

From cleaning in rivers or streams, the first recorded evidence of a dishwashing tool dated to 1850 when Joel Houghton made a simple hand-turned splashing device attached to a wooden tub. L.A. Alexander than added gears to a spinning rack that held dishes which can be spun inside a tub of water. This was further improved by Josephine Cochrane who made a wooden wheel lie flat in a copper boiler that could be turned by hand or driven by a power source via a pulley. She made wire frame compartments that fit her dishes to be attached to this wheel and the combination of it spinning whilst soapy hot water showered on them made it the first efficient dishwasher. It was soon patented and she opened a factory under the name Garis-Cochran Manufacturing Company to produce them, which then became part of the famous KitchenAid we know today. Dishwashers went on the way to become a feature in many Western households and it only made sense to be adapted to commercial settings.

Today, we tend to take for granted that a switch will get the job done because inventive minds have made things easier for home and the foodservice industry. In our Equipment segment on page 50, we go in-depth on the history and technology behind all that helps chefs achieve better productivity.