‘What’s Your Cut’ started off in the previous issue where we focused primarily on the various vegetable cutters. In this edition, meat preparation will be the focal point as we enlist the help of equipment manufacturers and business owners to collectively help you learn more about what’s available in today’s market and what is suited to your establishment. Food preparation equipment is a crucial stage between fresh food coming into the kitchen and being made ready for cooking or direct service into the restaurant. Now, these equipment range from the traditional hand-held tools such as knives and the specialty food preparation tools you find in a good chef’s toolbox to potato peelers, gravity slicing machines, juicers, multi-function food processors and combi-cutters. There is a wide range of food preparation equipment, but some are deemed most necessary than it being ‘nice-to-have’ and that also depends on the style of food the kitchen wishes to offer. In this issue, we’re get to the bottom of today’s meat preparation equipment.

A simple definition of the term ‘meat’ is a cut taken from the flesh of an animal, most often a mammal, which is consumed as food. The different cuts of meat have different names, depending on the animal, and are designated by primal and sub-primal cuts. For example, on a cow, the loin is a primal cut, and the short loin, sirloin and tenderloin are sub-primal cuts. There are

those that use regular hack saws, but the results are marginal at best. What you need is an actual meat saw, one that’s specially designed for cutting meat and bone. There are some important differences between meat saws, and their hardware store counterparts, which we will discuss as we go on.

This really depends on how many carcasses you intend to process, and how dedicated you are to using the very best ingredients in your cooking. Turkeys, chickens, and small game are not big enough to be worth using a meat saw on, at least if you obey the game laws on possession limits. But large fish that need to be steaked-out, and larger animals such as deer, hogs, cows, and big game are much better sliced with the proper tools, like the meat saw. For just one average sized carcass at a time, a manual meat saw works fine. For several large carcasses, or mule deer, elk, buffalo and other big boned meats, you will definitely want an electric model. You’ll see why in the next section…

COMPARISON OF MEAT SAW AND HACK SAW BLADES

COMPARISON OF MEAT SAW AND HACK SAW BLADES

If you look at the image above, you can see a somewhat significant difference between the meat and hack saw blades. Hack saw blades have very small teeth and is angled in a way to cut on both the for ward, and backward strokes. This allows them to be quickly clogged by meat fibres, fast, sinew and more. This also causes the bone to splinter rather than be cut. Wood saws will not work either because their teeth is designed not to clog up from meat and other materials. They slice rather than rip or damage. In turn, meat that is cut by meat saws will cook properly especially on a grill or in a pan; the meat sides have to be even so that it fully contracts the heating surface. Imperfect slices only get you some areas of overly charred meat, and other areas that will be underdone. Uneven surfaces conduct heat unevenly, so even if you are roasting, your meat will not cook well. Uneven surfaces will not allow the meat to sear properly, allowing the juices to escape resulting in tough, dry meat.

Another reason is that recipes are based on correctly cut meat. The pieces have to be right in shape, size and sur face, or the result may be different than expected. Meat that is mangled and improperly cut may not freeze right or thaw out evenly. There are two types of meat saws: electric and manual. In appearance, they resemble a regular table or hack saw. But in additon to the different blade style, they are also designed to operate at different speeds, be cleaned well, and sanitzed between uses.

USE, CARE AND SAFETY

USE, CARE AND SAFETY

Using a meat saw isn’t complicated as it’s a saw just like any other. The difference as mentioned previously is just the style of the teeth. However to properly process a harvested animal, you’re going to need to understand both the anatomy of the particular animal and the proper butchering techniques. Now, this isn’t an instructional on butchering but we do believe that it does go hand in hand as different par ts of the animal produce different cuts of meat, which differ in texture, flavour and cooking proper ties. Some are more feasible to smoking than others, and cuts that are intended to be smoked need extra care and diligence to smoke properly. That said, different cuts require different procedures such as sawing with the grain, against the grain, between joints, or across a particular joint of bone. Each particular cut will also require it’s own special trimming to cook properly.

A manual meat saw requires no set-up, other than really good cleaning and sterilisaton before use. This also includes your hands. Electric meat saws will require different set-up procedure, depending on the make and model. You should always follow the manufacturer’s recommended procedures every time you use their saw.

“Most people reading this probably realise that there is a danger of being cut, or even accidentally amputating fingers, or hands. After all, you are working around an extremely sharp, sometimes fast-moving blade. Most injuries with meat saws occur during cleaning, so exercise extra caution when cleaning and sanitising your unit. The most noted cause of all slicing accidents by far, is inattentiveness.”

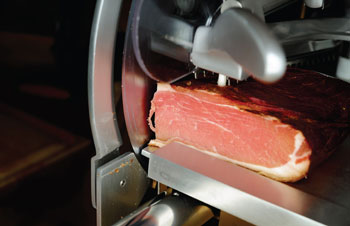

CHOOSING THE RIGHT MEAT SLICER

When it comes to choosing the right slicer for your establishment, understanding your needs and knowing your products are important pieces of information that will help make the decision making process a little easier. Slicing is all about strength. Whether you’re slicing fresh or frozen meat makes a significant difference and one of the key features you need to consider is horsepower. The duty your slicer needs to perform is directly related to the demands of your operation.

Sirman Palladio 300 Automec

Sirman Palladio 300 Automec

The Palladio Automec series offers the same outstanding features of the Palladio series adding a stainless steel base, piston/rod system carriage moton. Fan-cooled carriage motion motor with commercial-grade oil bath reduction. Blade and carriage motion powered by separate controls. An easily accessible switch arm can convert the unit from automatic to manual operation. The exclusive designed carriage, Netuno is available with a special end weight and an adjustable vertical product fence to provide stability and advance products evenly.

If your operation does, indeed, require your slicer to operate all day long, think about the difference between automatic and manual. Automatic meat slicers are perfect for busy environments. The carriage moves product automatically, without operator assistance. Designed with different numbers of speed settings, an automatic slicer also will allow you to set the number of slices per minute according to your volume, increasing efficiency and reducing waste. Manual meat slicers, on the other hand, require the operator to move the carriage back and for the to feed the food product through the blade. This means a little more work for you or your employee, but they are a great fit for operations with limited slicing requirements and limited space. They can also fit well with most budgets.

Look for NSF certifcation: The NSF certifcation means fewer seams, and a machine that is easier to clean. The blade should be built in and easily accessible, and either carbon steel, surgical stainless or a hardened stainless steel.

Your commercial slicer should disassemble quickly and without tools. Commercial meat slicers all share the same basic components such as:

Product Table, carriage, or product tray, is where you place the piece of meat, cheese, or vegetable to be sliced. These are often grooved and set at a specific angle so the product slides more easily toward the blade. On some models, this tilts up for easier cleaning.

Pusher: Also called “meat grip”.It is attached to the product table, and holds the product still while you’re slicing it. On some models, this is removable for easy cleaning.

Gauge Plate:This par t surrounds the knife. When you adjust the thickness control knob, sometimes referred to as index knob, this is what moves.

Sharpener:All slicers have a built-in blade sharpener to keep the blade razor-sharp and in perfect operating condition. Usually, it’s removable for cleaning.

Blade and Blade Guard:On most slicers, the blade is permanently attached to the unit and protected by a blade guard for safety. Depending on the model, the blade guard or ring guard is removable in varying degrees for cleaning. On some higher end models, the blade can be removed from the slicer using a special tool for a more thorough cleaning.

OTHER DESIGN FEATURES TO CONSIDER

OTHER DESIGN FEATURES TO CONSIDER

• Horsepower:Generally, higher horsepower slicers are designed for more frequent use.

• Blade Size:Mid Tier and Premium slicers usually have larger cutting blades (12”-14”) for all-around use, whereas entry level models often use smaller cutting blades (9” and 10”) for lighter use. Industry-wide, a 12” cutting blade is the most common size.

• Product Tray Size:Most slicers can hold products that range from 7 1/2” to 12” in diameter within the carriage. If you plan to slice products larger than 12”, it is important to verify that the slicer’s carriage will accommodate it prior to purchasing the slicer.

• Manual vs. Automatic:An automatic slicer, where an electric motor moves the product tray back and forth, is convenient when slicing large amounts of product because it can slice continuously without constant staff assistance. Automatic slicers can also be operated manually, so the main deciding factor is how much slicing you do. Large delis or supermarkets would see the most benefit from an automatic slicer.

• Belt Driven or Gear Driven:Nearly all of the slicers are belt driven. In theory, a slicer with a gear driven blade will be more durable, but in actual practice, if your geardriven slicer does require a repair, it will cost a lot more than simply replacing a drive belt.

• Cleaning Leg / “Kickstand”:Some slicers come with a special kickstand-style leg that lets you prop up the deli meat slicer to clean underneath it.

CLEANING AND MAINTENANCE

Food slicers should be sanitised on a daily basis. This can best be accomplished by using a properly mixed commercial sanitising concentrate and water. You can get professional meat slicer safety cleaning kit that comes with everything you need to help you safely clean and sanitise your slicer. It is important to properly lubricate each of the moving par ts within the feeder tray, as well as the carriage assemblies. By using a food-grade lubricant regularly, your slicer will be able to operate as smoothly as possible and last for years to come.

SAFETY AND DESIGN FEATURES

When you’re talking about a piece of equipment that’s operated by hand and uses a razor-sharp spinning blade to slice products, obviously safety cannot be understated. Proper training is essential for any employee who operates the slicer.

Knife Guard:Generally, all slicers expose as little of the blade as possible, to prevent cut hazards. On some slicers, you can remove it to clean the knife; on others it is permanently attached.

No-Volt Release:This safety feature requires the user to push the power button to restart the slicer after it has been unplugged for cleaning, or if the power was interrupted.

Gauge Plate Interlock:This feature requires the gauge plate to be set at “zero”to be able to tilt or remove the product tray/carriage for cleaning. This protects the blade’s edge and the operator’s fingers!

DECIDING WHAT’S BEST FOR YOU

When purchasing a slicer, it’s important to take into consideration exactly how much of what it is you intend to slice, as different slicers differ in capabilities for slicing meats, cheeses, and vegetables. While entry level slicers are of a significantly lower price than the larger, heavier duty models; they may quickly burn out if consistently pushed beyond their capacity. They are usually not designed to handle much.

Generally, heavier duty models also incorporate more usability and safety features. Depending on how much you use your deli slicer, you could make up the cost difference very quickly in increased productivity and safety, between a higher-end model and a less expensive option. In general, following these guidelines should help you find the perfect slicer for your facility:

• Entry Level Slicers are best suited for operations where the slicer would be used for an hour or two at most per day. While designed for simple, safe operation, they are not recommended for slicing cheese, and do not offer as many safety or convenience features as higher-end models.

• Mid-Tier Slicers generally have larger blades, a bit more horsepower, and can withstand more constant use than an entry-level model. Some models can handle occasional slicing of cheese, but are primarily intended for a few hours of vegetable or deli meat slicing per day. They usually offer a few more safety and convenience features than an entry-level model too.

• Premium Slicers represent the top-of-the-line offerings from each manufacturer. Most are designed for heavy duty, constant use, and can slice cheese as well. These models offer design features that enhance the smoothness of operation, slice precision, and safe operation.

TYPES OF MEAT GRINDERS

Commercial meat grinders are available in a variety of sizes and confgurations. Manual meat grinders mount to your table or counter top and are specifically designed for low volume use. And, due to their relatively small capacity and the need to turn the crank by hand, this type of grinder likely won’t be used too often in a commercial setting.

Commercial meat grinders are available in a variety of sizes and confgurations. Manual meat grinders mount to your table or counter top and are specifically designed for low volume use. And, due to their relatively small capacity and the need to turn the crank by hand, this type of grinder likely won’t be used too often in a commercial setting.

Sirman T32 Buffalo

Sirman T32 Buffalo

The TC32 Buffalo meat mincer is specially designed for heavy duty operation, high output and top quality mincing. The perfect choice for large butchers and meat processors. An exclusive fixing system allows the mouth to be removed quickly and easily for cleaning while also ensuring perfect locking during use.

Electric meat grinders come in a variety of sizes, from small counter top units all the way up to large, high output for mounted models that are best suited for meat processing facilities or busy butcher shops or meat counters. It’s important to pay attention to the amount of meat a particular meat grinder can process per minute (or per hour) when comparing models. If you purchase a unit that can’t keep up with your output requirements, your machine’s lifespan is shortened immensely and will negatively impact your own productivity.

Purchasing Consideratons

• Match the output of the machine to your business needs

• Pay attention to the materials and constructon of the grinder; stainless steel is dishwasher safe and resists corrosion

Hobart 84186-1 Buffalo Chopper

Hobart 84186-1 Buffalo Chopper

Chop and puree even the toughest ingredients using this Hobart 84186-1 buffalo chopper food processor. This chopper has special cutler y-grade, stainless steel knives that are capable of cutting down tough proteins in minutes. In terms of production, this unit’s 1 hp motor, is built for high production use as the blades rotate at an impressive 1725 RPM. The #12 hub accommodates any of Hobart’s #12 attachments, including various slicers and meat choppers.

Buffalo choppers (also known as horizontal cutters) are an extremely versatile piece of equipment that are able to shred chicken, pork, and other meats that you don’t necessary want finely ground. They also work great for making things like coleslaw, potato salad, chicken salad, and more because you can add seasonings and sauces as you’re cutting the meat or vegetables. Some models even boast a powered take-of hub (PTO) where you hook up a meat grinder or vegetable slicer attachment to have the best of both worlds!

Purchasing Consideratons

Purchasing Consideratons• Decide whether you want to purchase a model with a #12 hub

• Pay attention to safety features; the blade is more exposed on this type of unit

• Evaluate space; these models can take up a bit more counter top space than a traditonal counter top meat grinder

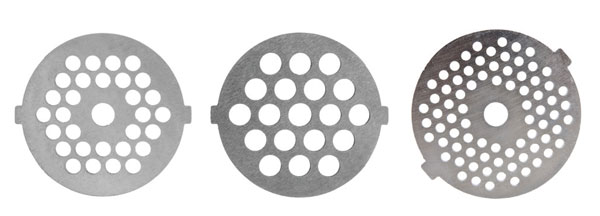

ACCESSORIES AND ATTACHMENTS

Multiple Grinding Plates

Most meat grinders come with several sizes of grinding plates or dies, with holes of varying sizes. And with many manufacturers, additional sizes are available for purchase separately. Obviously, the smaller the holes, the more finely ground the final product will be. For the smaller grind sizes, it’s best to grind the meat star ting with the largest hole size first. Then, re-grind the meat through smaller grinding plates to achieve the best results.

Sausage Stuffer Atachments And Sausage Stuffers

Sausage Stuffer Atachments And Sausage Stuffers

Many meat grinders have an sausage stuffing tubes that are optional of var ying sizes that you can use to grind meat directly into casings for hot dogs and sausage. Using a stuffing tube with a meat grinder, particularly if you don’t have a “stuffing die”, can be a slow process because the machine doesn’t output the ground meat nearly as quickly as a dedicated sausage stuffing machine. If you want to produce a lot of sausage or hot dogs, you’ll be much happier and more productive with a standalone sausage stuffier.

Meat Mixer

This is a relatively simple product, where ground meat is added. Seasoning is then added to a hopper and you turn a crank to mix the product together. This is great for sausage, meatloaf, meatballs, and other seasoned meat products. A few of the largest commercial meat grinders we offer have this capability built-in, which is helpful for food processing or extremely high output situations.

MEAT GRINDER TIPS AND TRICKS

Follow these recommendations to get the most out of your purchase!

• Most commercial meat grinders are not designed for animal bones.

• Don’t take your meat out of the refrigerator until you’re ready to grind it.

• Chill your grinding plates, knife, feed tube, and auger in a freezer or ice bath before grinding a batch of meat. Since grinding creates friction and will warm the meat up, keeping everything as cool as possible will help with food safety!

• Cut the meat into evenly sized chunks and feed it through the funnel gently; don’t force it!

• A sharp cutting knife is a must. Replace dulled ones for better performance!

• Thoroughly clean and sanitise all components immediately after use. Most stainless steel components are dishwasher safe.

• For cast aluminium or cast iron components, try storing them in a small food pan with some cornstarch or desiccant. It will absorb excess moisture.

• Use a food-safe lubricant to maintain and protect all moving parts.

Some restaurants or hotels might have to forego manual and in-house butcher y due to space or lack of skill and choose to go with pre-cut meats. This eliminates the labour and yield loss involved in producing the cut. This may cost a little more but there are companies in the market that allow you to customise your pre-cut meats based on budget and needs. This is where Global Livestock Services come in.

Some restaurants or hotels might have to forego manual and in-house butcher y due to space or lack of skill and choose to go with pre-cut meats. This eliminates the labour and yield loss involved in producing the cut. This may cost a little more but there are companies in the market that allow you to customise your pre-cut meats based on budget and needs. This is where Global Livestock Services come in.

WHAT’S YOUR CUT? : MADE FOR YOU

Global Livestock Services market high quality meat and co-products to local and international markets which comply with Malaysian Halal requirements. The company’s products have met quality controlled systems and are approved by Department of Agriculture, Fisheries and Forestry and AUS-MEAT.Global Livestock Services personnels have been involved within the Australian export meat industry with over 35 years experience,the business was registered as a partnership entity with five core directors. The company began its research in 2013 into supplying red meat into south east asia. The company has successfully registered a Malaysian based entty and obtained an import license to supply and distribute red meat products within Malaysia. We speak to GLS to find out what sets them apart:

MEP: What kind of delivery services do you provide?

MEP: What kind of delivery services do you provide?

GLS: We provide delivery services via refrigerated trucking system and as for the new outlet, we will be introducing a Home Delivery Service to our customers via a specially designed refrigerated chiller and freezer box mounted on a motorbike. The concept of this motorbike is the first in Malaysia. This motorbike deliver y vehicle project was in collaboration with the University of Malaysia Perlis to suit our customer’s need for fast and efficient delivery. The unique part about this system is it stays chilled and frozen at the same time. It can carry weight up to 80kg per ride.

MEP: How does GLS engage with its customers and the industry?

So far, at GLS we have an ongoing consultation with our customers to ensure that the product supplied is meeting their needs. We endeavour to meet our customers personally and discuss their requirements, concern and needs. We also offer various ways of preparing meat for retail and wholesale from general public to high-end users as we can provide the products in various weights or volume depending on their needs. We connect with people who have passion for food industry especially in meat production. We share ideas and provide assistance where possible. We are passionate about lifting the standard of meat industry in Malaysia and educate general public about meat safety and quality to improve their general health and wellbeing. In terms of the future, there will be a reward card system implemented very soon and in conjunction to that, we are establishing our online service that customers can order the products at the click of their fingertips.

MEP: What do business owners need to know about the meats you provide, and which types are suitable for certain kinds of businesses?

MEP: What do business owners need to know about the meats you provide, and which types are suitable for certain kinds of businesses?

All the meat used at our premise are JAKIM Halal Accredited. Be it a primal or sub-primal cut, we ensure that products are of high quality and meet all the meat safety standard. We can source meat from various countries but predominantly focus on products from Australia. Our products are mainly chilled and frozen beef, lamb and mutton. We also offer value-added products as mentioned earlier in the first question.