We live in a world that consumes more energy than ever. We hardly think twice about flicking that switch or plugging in our multiple devices. In United States of America, an individual is estimated to use approximately up to 148,600,000 BTU of energy annually – equivalent to having the energy from eating 117 burritos a day! The numbers are staggering if you factor in the manufacturing industries. Indeed, the call for environmental conservation is resounding louder than ever; with the growing population and industries striving to keep up with production to satisfy necessities and material desires. Climate changes, a thinning ozone layer, poorer air quality, soil degradation; the effects of mankind’s actions are known to all and much needs to be done.

Earth Day is in its 45th year and this year, it is encouraging the world to take the lead, where “world leaders finally pass a binding climate change treaty”, “which citizens and organizations divest from fossil fuel and put their money into renewable energy solutions”. What do these mean for the food and beverage industry, admittedly one of the largest stakeholders on the environment with our equipment usage, food wastage and contribution to water and air quality? We are sure the solutions are endless but here are some approaches that reflect responsibility to Earth, even to our health, to a certain extent, from manufacturers’ and foodservice operators’ viewpoint.

OUR FOOD & THE ENVIRONMENT

• While it is expected that technology replace human labour in the industry, households are also contributing to extra energy use by using electronics instead of traditional ways in preparing food and washing.1

• Food processing industry works to meet demands for prepared food and items like “single serve” requires more packaging materials which means the use of more raw materials.1

• The entire food chain comprising retail, preparation and cooking, processing and distribution, production of fisheries, livestock and cropping; including landfill gas produced from food wastes account for approximately 22% of total greenhouse gases emissions.2

• Our soil is experiencing nutrient depletion, possibly due to fertiliser use and monoculture planting methods3 where a single plant is grown over the same area year after year which can lead to a quicker spread of pest and diseases.4

• In the year 2010, United Kingdom recorded the food and drink processing industry as the fourth highest industrial energy user by consuming enough energy to power 125,000 homes for nearly 15 years and emitting around 11 million tonnes of carbon dioxide into the atmosphere.5

1http://grist.org/article/food-our-energy-gulping-industrial-foodsystem-in-eight-bullet-points/

2Giampietro, 2002; Smil, 2008; IEA, 2010; Woods et al., 2010; GoS, 2011 and others. www.fao.org

3http://www.takingcharge.csh.umn.edu/explore-healing-practices/food-medicine/how-are-food-and-environment-related

4http://en.wikipedia.org/wiki/Monoculture

5http://www.carbontrust.com/resources/guides/sector-basedadvice/food-and-drink

Hold-Line keeps the buffet line warm at Ethiad Tower Rosewater Restaurant

Max Kaufmann in the Alte Krone kitchen

WHERE COOKING IS CONCERNED

Stovetops hunger for energy and when chefs fire up the stove, the same amount of energy is used to light the hob, regardless of the pan size, which means wasted energy is a common occurence. To overcome this issue, induction is the answer for now. Using magnetic energy, coils of the stovetop generate electromagnetic fields that react to warm a steel-based cooking vessel placed on it. Energy is transferred to the base of the cooking vessel to cook the food and when the vessel is removed, heat transmission stops immediately; thus saving energy. It is estimated that less than half of the energy in gas is eventually used to cook whereas about 84% or more of energy in an induction cooktop is used; resulting in better cooking efficiency and a cooler kitchen. Without open flames, cooking is safer and an induction stovetop, while it is warm to touch after the vessel has been lifted up, it is not hot enough to cause harm. The positives of induction has resulted in companies manufacturing them for industrial standards while foodservice operators begin embracing it.

Induction Concept Systems (INDUCS)

Presenting the industry with equipment founded upon induction heating, INDUCS range include induction units for cooking, frying and heat retention (particularly for buffet lines). It engineered the RTCSmp Realtime Temperature Control System; the first and only all-round control and monitoring system for induction technology with:

• Electronics temperature monitoring

• Induction coil temperature monitoring

• Energy input monitoring

• Regulation in real time

• Importance on workplace safety

• Controls and monitors from overheating at the pan base

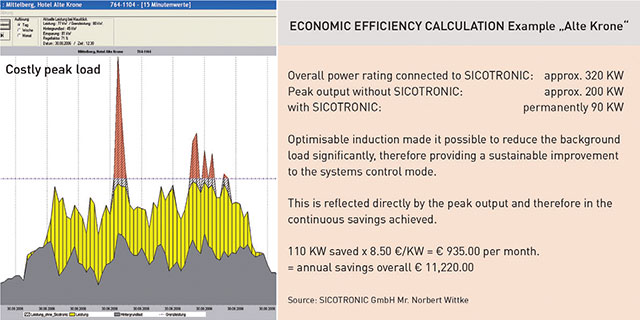

In further developing the RTCSmp concept, INDUCS worked with an energy management systems company, SICOTRONIC and the RTCSmp inductions systems was created. RTCSmp works by communicating with the induction generator to ensure the correct amount of power is sent to the vessel to maintain the proper temperature – automatically. This enables operators to shave off more energy consumption with the kind of precision the system offers and Max Kaufmann, operator of Alte Krone resort attests to it.

Up in Mittelberg (Austria), the resort was one of the earliest adopters by switching gas cookers to INDUCS induction systems in 2004. Max Kaufmann, a third generation operator of the resort believes the ability of induction to improve economies of efficiency. In 2009, it became the world’s first to operate an energy-optimised induction hob where induction generators RTCSmp were installed externally on the cellar ceiling and the system uses continuous comparative measurements providing each device with the maximum amount of energy it needs in actual real-time.

For more information on INDUCS , visit www.manitowocfoodservice.com

THE FRONT COOKING AMBIENCE

Unless one is cooking outdoors, ventilation is necessary even on domestic levels, what more in commercial settings? Ventilation generally means to provide healthy air for breathing within confined buildings by diluting and removing the source of pollutants. In the case of

kitchens, the environment is almost always permeated with smoke emissions, grease and is a hot place to be in, plus the impact it has on the environment. Hence, air cleaning installations is compulsory in foodservice settings. While we enjoy our food, we don’t often think

of behind-the-scenes. Yet, as concepts and curiousity evolved, front-of-house cooking has captivated diners and is presented as an upscale, unique experience. Having said that, how are businesses doing this and still keep its ambience clean and classy?

Taking a case study of The Shard, Oblix Restaurant in England which desired to offer sophisticated and upscale urban dining on the 32nd floor devoid of grease, smoke or odours discharged to the atmosphere. While heavy duty cooking appliances like char grills and rotisseries required precise filtration installation, the site also posed additional challenge with its high airflows and low slab heights. The two key considerations were to enable customers to walk through the kitchen, watch the chefs in action whilst heading to their tables and with the show kitchen canopy being decoratively clad, how would it introduce supply air without affecting the balance of the kitchen area?

Building of The Shard,

Oblix Restaurant

Front-of-house kitchen in The Shard

Halton’s Precise Technologies

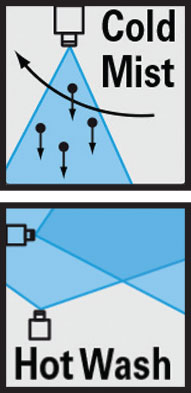

Cold Mist reduces temperature of the air, neutralises potential sparks and removes grease from the exhausted air combined with intercepting baffles in the exhaust plenum prevents grease deposits from building up in the ductwork while daily hot Water Wash automatically removes grease deposits from the plenum.

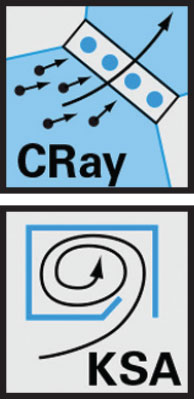

UV-C Capture Ray is the second layer in neutralising grease particles, grease vapours and organic compounds and is usually combined to the efficient KSA cyclonic mechanical filtration that limits grease deposits from building up inside the exhaust plenums of hoods and ventilated ceilings.

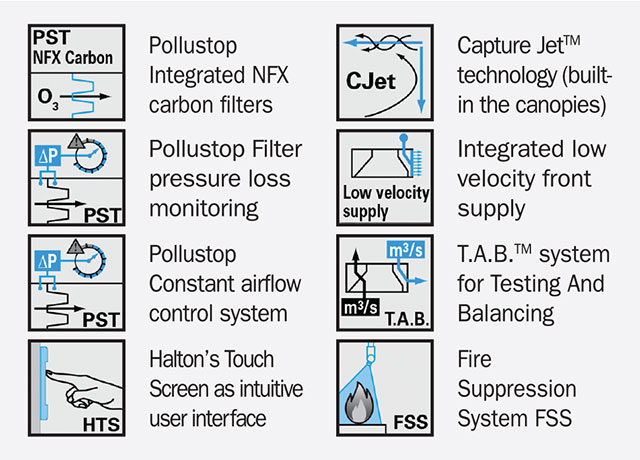

POLLUSTOP Air Purification Unit [PST]

A standard range of modules designed for incorporation into kitchen ventilation systems where control of airborne pollutants at the discharge point is required. It is predicted that legislation would be put in place that makes it compulsory for any business that takes in fresh air, as part of its processes, to return that air to the atmosphere in good condition. It is especially developed for commercial kitchens running in dense urban locations with these benefits:

• Low level discharge for exhaust ductwork

• Minimal cooking odours and pollution resulting in better external quality in surrounding areas

• Sustainable due to lower energy consumption in an efficient heat recovery system

A typical configuration of a PST unit consists of 8 modules:

For more information on ventilation solutions, visit www.halton.com/foodservice

BETTER SANITATION

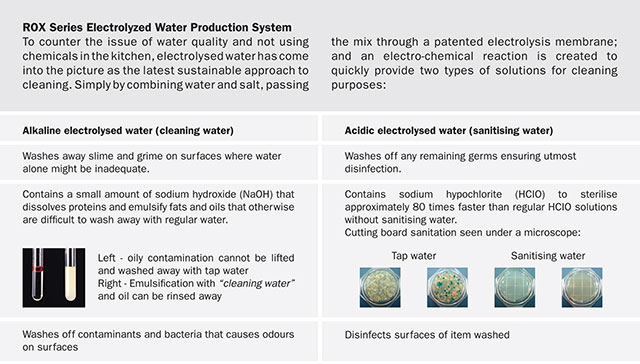

When we talk about eco-friendliness, the discussion often revolves around how to compact energy usage of our ovens, stovetops, refrigerators and other large equipment. However, the environment’s wellbeing and also our own can benefit from daily actions, for example, the area of sanitation.

Sanitation management involves stopping contamination in its route to food that causes food poisoning. Primary contamination relates to food being affected from its natural environment or contamination present at the time food is received. At the back-of-house where chemicals have no place, we have used water all along. Yet, our water is no longer as clean today and with increased use of pesticides on produce, we began doubting the cleanliness and safety of our food. Meanwhile, secondary contamination happens when utensils and counters used in food processing coming into contact with food handler’s hands and other point of contact. In terms of non-food items, operators have been using chemical solutions to get rid of bacteria as much as possible yet with the rise of consciousness, many are also trying to use less or completely avoid using chemicals in their facilities.

The ROX system is designed to fit easily above water outlets for the dispensing of water while the compact system will fit under sinks. To further enhance hygiene, it runs on a touchless operation where users only need to hold up their hand to the sensor for water to

be distributed. Equipped with flexible nozzles that can be bent to any angle, water can be dispensed either in a straight or shower flow. Amount of water can be predetermined with a timer that turns on and shuts off accordingly. Foodservice operators are seeing the

eco benefits of electrolysed water, how it is better for the health of its customers and employees alike; and how it is able to cut cleaning cost as it only utilises tap water, electricity and salt instead of bottles of cleaning solutions previously stored in a kitchen’s storeroom.

Left to right:

Wall unit and picture of ROX’s entire unit

For more information on electrolysed water systems, visit www.hoshizaki.com.sg.

Is your sink wasting resources?

KEEPING TABS ON THE SINK

Let’s look inside the sink, how much of resources get washed down its pipes when a kitchen washes produce, cutlery, utensils and everything else? The amount of water, cleaning detergent and manpower used runs high on each restaurant owner’s bills. It is common logic that the larger the surface or the deeper a vessel, it will require extra resources to complete the task. When dishwashing machines first came into the picture, the catering industry was abuzz as they did not need to wash hundreds of plates by hand anymore and as technology advanced, machines also became more eco-friendly and cost effective to operate.

PowerGranules that go the distance

However, there was still the issue of large pots that either do not fit into a regular dishwasher and had to be handwashed or would still require presoaking and scrubbing before going into a warewasher for a cleaner result. A warewasher is not able to completely rid pots soiled with thick sauces, crystallised sugars, melted cheese, hardened pastry crusts or grease. It was something to think about, what if you could skip the soaking and scrubbing hence saving resources?

Granuldisk Power Granules

What if sinks are the biggest energy wasters? Now, that might not make sense at all as sinks don’t run on any horsepower but Granuldisk saw that the traditional pot washing process of pre-soaking and scrubbing eats into the environment although the automated machine could be saving a few kWh or centilitres of water by washing faster with less cleaning agents. It proposes that operators look at the real issue which is the pre-wash process. Hence the invention of its PowerGranules. The blue granules are made of plastic approved for use by the FDA (U.S. Food Drug Administration) when in contact with food and harmless in case of ingestion. They are hard enough to clean effectively, but at the same time soft enough not to damage the goods or the wash system.

Its pot washing machines work with a combination of PowerGranules, water and a small amount of detergent to mechanically scrub pots and pans clean. Using high temperature washes and blasting power, users only need to scrape of solid food residues and load the pot and pans into the machine. The Granules hit the surface with a speed of more than 200 metres per second, equivalent to more than 80,000 hits, every second to create the abrasive effect that cleans the pan in minutes. Granules are then separated to make way for the rinse cycle that completes the wash.

Adding to the environmental-friendliness, PowerGranules are reusable up till 2500 – 3 500 cycles, depending on most frequently used programs, machine type and what items are washed. This translates to washing approximately up to 20.000 GN 1/1 pans before you need to exchange the batch of PowerGranules in the wash tank. Granuldisk’s technology has proven to be a sound investment for large scale operations as “our clients often reduce consumption of water, energy and chemicals by up to 60 % while at the same time ensuring top hygienic wash results”, says Cecilia Carlsten, Product Manager at GRANULDISK.

For more information, visit www.granuldisk.com

![]()

For more information, visit www.granuldisk.com

THE MANUFACTURERS’ VISION

From products that operators can select to use for the betterment of the environment and health, manufacturers are also taking up the task of being accountable for how they make their products. Indeed, if we are to talk about cutting down on our detrimental actions, a collective effort will be needed and these companies are doing what they can in responsible manufacturing.

What’s In Plastic Products?

If you walked around a department store looking at plastic items, perhaps you would have noticed a BPA-free label on many of them. BPA stands for Bisphenol A which is a carbon based synthetic compound, colourless and soluble in organic solvents although poorly soluble in water. Discovered by Russian chemist Aleksandr Dianin in 1891 and was used since 1957 in the making of plastics and epoxy resins, BPA based plastics are clear and resistant while epoxy resins with BPA is adapted into lining water pipes or used as coatings on the inside of many food and beverage cans. It came under scrutiny when the 2003-2004 National Health and Nutrition Examination Survey (NHANES) conducted by the Centers for Disease Control and Prevention (CDC) found detectable levels of BPA in 93% of Americans 6 years and older. Together with it presenting hormone-like properties and possibility of leaching out of products if subjected to high temperatures, some countries have banned BPA in baby bottles. Although the US Food and Drug Administration (FDA) concurred that the very low levels of BPA in food-related products are unlikely to be harmful to human health, the US Environmental Protection Agency did report that over 1 million pounds of BPA got into the environment just in the year 2010. The compound was found to interfere with the growth of some leguminous plants as well as affect growth, reproduction and development in aquatic organisms; prompting companies to reconsider their stand on the matter.

Electrolux goes BPA-Free

The BPA ‘ban or not’ debate is still ongoing as of 2014 but for Electrolux Professional, it has decided to discontinue the use of BPA in all plastic components in its Food Preparation range due to the items coming into direct contact with food. Spanning a complete range of

appliances that include vegetable slicers and peelers, food processors, planetary mixers, hand mixers, combined machines and much more, food processing equipment have become indispensable to chefs in large-scale culinary settings as well as spurring their imagination in creating dishes with a variety of shapes and textures. It is both a step towards sustainable innovation for every individual with a possibility of encountering food items produced via Electrolux’s Food Preparation machine as well as one that is kinder to the environment. “We are particularly proud of this achievement, which reinforces Electrolux Professional’s leading role and proactive approach in implementing effective measures to ensure safety, hygiene and quality. From the 100% dishwasher safe components of the range’s bestsellers to the elimination of BPA, the company has once again shown how its pursuit of responsible innovation to guarantee and promote food safety is a core priority and source of inspiration that drives the entire development process in Food Preparation.” (Elena Gollino, Electrolux Food Preparation Professional Product Manager). From 2015, all plastic components in Food Preparation equipment that come into direct contact with food will be BPA-free and labelled accordingly.

For more information, visit http://www.electrolux.com/professional.

BEING “LEAN & GREEN”

Companies that manufacture are aware of the carbon footprint trail that equipment can leave behind. Hence, the continuous work on bringing up the ‘green’ factor to match users who are also interested to be responsible in their operations. What if manufacturers put more thought into the impact beginning from the inside of their factories? This is the aim of the Lean & Green approach, a non-profit Dutch network founded by Connekt for sustainable mobility. The stimulation programme for businesses encourages companies and government bodies to move their operations to a higher level of eco-conscience with measures that save costs and reduces the burden on the environment. It is based on three organisation pillars that are Lean and Green Logistics, Lean and Green Personal Mobility as well as Lean and Green Barge (inland shipping in the container chain). A voluntary certification, an organisation needs to demonstrate to the network its plan of action that will be able to reduce its Co2 emissions by 20% within five years and will be awarded its first Lean and Green Star for meeting the goal. The award testifies that the organisation is actively engaged in making their logistics, mobility processes and management more sustainable.

Rational, a two-time recipient

One of the world’s leading provider in combi steamers, while seeking to offer maximum benefits in hot food preparation in large-scale and commercial kitchens, it is well aware of the sort of impact its manufacturing process can have on the environment. Awarded the “Lean and Green Award 2010” for energy management, energy-efficient buildings and processes and recently attaining the “Lean & Green Management Award 2014” – a demonstration of its continuous commitment to be more efficient in handling energy, water, waste and sewage aspects. Although these awards are measurable platforms, the company has been working with principles of responsible and sustainable activity since its establishment in 1973 which extends from product development, via production through to the planning of sales visits and disposal logistics. Any ideas that the team has must have an environmental edge alongside economic sustainability before implementation and the company was definitely tracking it right as we now live in global agreement that saving energy is necessary

due to the worldwide scarcity of raw materials. With more than 80 engineers, physicists, nutritionists and chefs in its development team, new technologies are investigated and developed via research projects with institutes and universities. Conducting regular exchange of information between the cooking research process and their customers helps the manufacturer to constantly optimise cooking paths towards improved energy and water consumption of Rational units.

For Rational, the joint venture between industry and consultants which are based on lean thinking philosopies and forward-looking technologies have resulted in approaches such as designing the modern hall at an angle where natural light comes in thus reducing use of artificial lighting while innovative overhead heating technology in the factory means air conditioning runs more efficiently. An open-pored, water-permeable covering is used for all public thoroughfares allowing all rainwater to seep away to an allocated space for further purposes. Waste in production is undeniable and to reduce waste in landfills, a consistent separation of waste is sent to recycling systems or reused to generate power. The company ensures that bought-in parts exist of 100% recyclable packaging materials where possible while innovative unit packaging cuts down waste volume. “The Lean & Green Management Award gives our customers a sense of security to cooperate with a responsible and ecology-minded partner, who supports efficient usage of resources”, states Millie Chan, Vice President Business Development Asean of Rational.

To understand Rational’s environment policies, visit www.rational-online.com

For more information

about Lean & Green, visit http://lean-green.nl/

http://energy.gov/articles/how-much-do-you-consume

http://theinductionsite.org

http://en.wikipedia.org/wiki/Bisphenol_A#

“Bisphenol A (BPA): Use in Food Contact Application”. Fda.gov .

Fox JE, Gulledge J, Engelhaupt E, Burow ME, McLachlan JA (2007).

“Pesticides reduce symbiotic efficiency of nitrogen-fixing rhizobia and host plants”.Proc. Nat. Acad. Sci.

http://www.chemicalsubstanceschimiques.gc.ca/fact-fait/bisphenol-aeng.php “Bisphenol A Fact Sheet”.