A chef’s knife skills is undeniably vital but in certain situations, one knife and a pair of hands can only do that much. When there are 100 carrots to cut to a consistent thickness and size; together with plenty other tasks in the way, choosing to use a food preparation machine proves to be the smartest move.

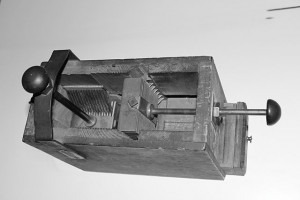

This realisation dawned upon Mr Ernst Hall, one of the founders of the now worldly-recognised HALLDE brand specialising in food preparation equipment for commercial kitchens. But it was not his first invention; the company was started upon a butter portioning machine that makes spreading butter easy yet keeping the pieces presentable. It was a typical Swedish dish known as “Jansson’s Frestelse” (Jansson’s temptation) that sparked the idea of making the job of slicing potato into 4x4mm pieces easier for his wife. He came up with a hand-held box where embedded knives cut potatoes into julienne. The invention excited him and he continued experimenting and soon the first machine to prepare vegetables in bulk was a reality.

The Vegetable Preparation Machine caught on and soon became an all-in-one machine that helped the kitchen crew slice, dice, shred, julienne and grate all sorts of vegetables. While it may look like an expensive and unnecessary equipment to have 70 years ago given that the eating out culture only began much later, HALLDE made great strides. Sweden was a country relatively welloff despite World War II and with the good standard of living, the production industry grew. The growth meant a healthy workforce and companies saw the need to improve efficiency in serving the employees and saw HALLDE’s equipment as a solution. From production kitchens to institutions, the machines is part of the government’s requirement for schools to adopt a holistic approach to nutrition and diet and with vegetables a great part of the plan, doors continued to open for the company.

DOING ONE THING AND DOING IT WELL

Knowing what it does well and harnessing its strength is something HALLDE got right and the manufacturer keeps itself rooted. What started in a small basement in the central of Stockholm in 1941, the growth has made it necessary for expansion and all machines are still assembled in the factory in Sweden together with its office. It also aims to engage with its customers and dealers through education about the technology behind HALLDE’s machines at its Food Preparation Academy that runs seminars and product demonstrations; an exercise that is crucial to provide a real-life experience and increase its brand retention in the marketplace.

A business thrives on people and as much as customers keep it afloat, so do its employees and HALLDE looks into the safety and wellbeing at its production plant. With cutters that can produce up to 3,000 portions a day, it is surely no child’s play and makes ergonomics an important area for HALLDE as ease of handling minimises the risk of untoward accidents. This is in line with equipment being easy to use by any one, reducing the need for training new employees as the workforce in the foodservice industry experiences a fairly high turnover rate. The same principle applies at the plant where heavy lifting is avoided and tools arranged in a way that offers easy access and machines used to make equipment are adhering to industrial safety certifications. All these measures result in HALLDE being certified in accordance with the ISO9001 while products are in line with hygiene, safety and quality standards like NSF, UL, EEC and CE.

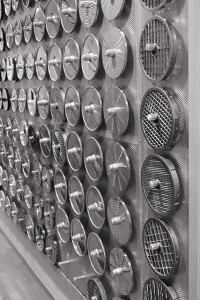

A commercial kitchen operates with a wide variety of equipment and with its well-equipped manufacturing facility; it is not beyond HALLDE’s abilities to venture into making more different equipment. Yet, it chooses to improve on its vegetable preparation forte as well as related items like blenders and mixers that makes blending, chopping, mashing, stirring and grinding an easy task while Combi Cutters fuses a vegetable preparation machine and a mixer/blender together. It aims to be a world leader in the manufacturing of these equipment and dedicates its time and expertise in developing better machines for its customers in view that they play an important role in the kitchen (despite its compact sizes). Different cuisines or dishes require individual cutting dimensions and users can substantiate machines with over 50 different cutting tools including dicing grids. To give customers a complete set-up and better convenience, accessories like container trollies, machine tables, wall racks and knife guards are available. Food preparation equipment is essential in any kitchen size and HALLDE’s machines have proven its worth from a fine dining restaurant in Kuala Lumpur all the way to production plants far out in the country sides.

MOVING ONWARD WITHOUT DIVERSIONS

Approximately 85% of its products are exported worldwide; and sold in more than 80 countries over the world through more than 200 representatives, HALLDE will continue its efforts in penetrating more market segments. Good products will remain so without the art of marketing and HALLDE’s consistent presence at exhibitions gives them the edge to get a contact point with greater customer demographics and actively uses creative advertising to attract the attention of the audience it does not meet. “Poor customer service!” is a label that no brand wants to have on them; as the foodservice industry is such a fast paced one, no kitchen can afford a long downtime. Preparation is the start of any cooking process and HALLDE’s products are instrumental to keep the crew on time thus it educates its dealers’ sales team and ensures that there is a service available at all locations where its products are used. To enter more new markets, the sales team moves around the world, observing the dining culture as well as local and international trends that helps in generating better equipment for customers in a particular region. In an industry that is always growing with rapid evolution, food preparation equipment will always have a space on the worktables of a commercial kitchen and HALLDE is here to stay.

hallde.com