It is a global regulation that foodservice facilities install a grease trap to intercept grease before they enter a wastewater disposal system. Due to the differences in kitchen sizes, grease traps are not made equal and a correct sizing procedure is needed before installation. The size of traps are manufactured according to the rate of incoming flow, using the term gallons per minute (GPM) which relates to the traps’ capacity which measured in pounds will be twice the flow rate such as a 20GPM trap’s rated capacity is 40 pounds. It is recommended that you round up to the next available size when calculating. In general, there are three types of grease traps and most kitchens would pick one according to its production capacity.

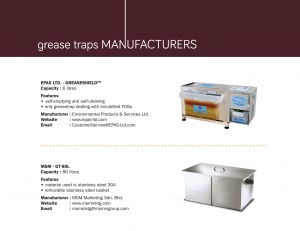

The most common one is the passive grease traps which comprises small point-of-use units under sinks within the kitchen. It can trap about 85-90% of fats, oils and grease and is usually adequate for individual restaurants. As wastewater flows through the unit, the grease rises to the top of a small baffled tank which keeps the grease toward the upstream end, stopping it from going downstream where it can cause blockage. Typically sized from 20-25 gallons, the trap must be cleaned regularly and monitored though technology has enabled some grease traps manufacturers to offer equipment that self-cleans as well.

In places like banqueting or institutional kitchens, they should get the large in-ground tank that range between 500-2000 gallons to be able to hold larger amount of grease. Also known as gravity interceptors, they are made of concrete, fibreglass or steel. It will need about 30 minutes for the fats, oils, and grease and food solids to settle in the tank.

Read more about FOG management in the Solution Provider section.