The analogy of “Everybody waits for Somebody to do it but Nobody did, yet it was a task Anybody could have done”, is a famous one when it comes to clarity in responsibilities. In a commercial kitchen, work is known to get hectic and with so many machines used, daily cleaning is vital as a course of action in preventive maintenance.

The analogy of “Everybody waits for Somebody to do it but Nobody did, yet it was a task Anybody could have done”, is a famous one when it comes to clarity in responsibilities. In a commercial kitchen, work is known to get hectic and with so many machines used, daily cleaning is vital as a course of action in preventive maintenance.

Some food borne illnesses have been found to be caused by using equipment that was not clean and needless to say, an incident that leaves a huge dent to an establishment’s reputation. Aside from food safety, it is about the lifespan of a machine and having it perform at tip-top level at all times. After all, any machine in a commercial kitchen does not cost peanuts and proper care plays a significant role in reducing repair costs and the frequency of buying new ones. Systematic documentation will also assist in deciding if it will cost more to repair or to replace, especially if the log shows that the particular equipment requires frequent servicing that most likely disrupts operations and is an unexpected cost. Well- functioning equipment translates to smooth operations in a facility, helps in achieving standards in food safety and as a means to document machines’ performance. To ensure that equipment gets the care it deserves, operators are advised to set up a maintenance program that streamlines all procedures.

WHAT EQUIPMENT DO YOU HAVE?

WHAT EQUIPMENT DO YOU HAVE?

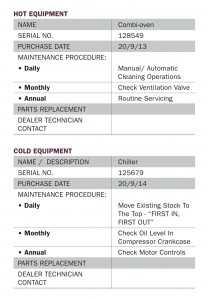

Depending on the size of your facility, the maintenance program may differ but to start off, take inventory of equipment in the facility. A simple table, which you can refer to as ‘master list’ puts in place the details of each item. It is also likely that most pieces of equipment require different maintenance schedules. They may need to be serviced after daily use, have parts replaced every few months and sent for more complex maintenance annually. Thus, in your inventory, be as detailed as possible so you can look up maintenance records easily and ensure that everything is done accordingly. Here is an example of a master list that you can apply.

PUTTING TOGETHER A MAINTENANCE DUTY ROSTER

PUTTING TOGETHER A MAINTENANCE DUTY ROSTER

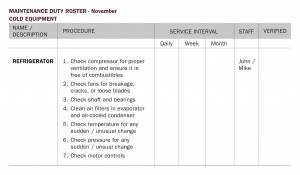

While equipment manuals provide very detailed instructions on maintenance, more often than not, there is too much to go through. Hence, managers developing the schedule should read the manual, extracting only the necessary instructions. A work schedule can include a title to describe which segment of equipment it refers to, job scope and the person responsible who needs to take note what he / she has

done and present it to the manager (who should check the work quality first) before verifying that the task was performed properly.

When writing the step-by-step procedure of maintenance, use bullet points and in short, concise sentences for ease of understanding. Categorise equipment according to type and use columns and checkboxes so that staff on duty can check-off instantly what is already done. The rotation may depend on how many pieces of equipment the kitchen has and how many staff is trained to carry out the maintenance work. A suggested timetable as below covers daily, weekly and monthly requirements and you can adjust to include additional intervals.

CONTINGENCY PLANS

CONTINGENCY PLANS

While care is taken according to schedule, there is no telling when a certain part of the equipment breaks down, hence it can be helpful to also have an inventory of spare parts. You can keep backup parts within your facility but most business owners do not due to lack of space and the additional cost required in buying parts for each piece of equipment. Depending on the problem, some machines can still run with a temporary fix while waiting for the proper spare part to be delivered. However, in this case, the manager would need to assess whether it is worth the time to temporarily fix it if the problem can be rectified in a reasonable time frame or it makes more sense to shut it down. If executing a temporary fix, make sure that the fix will not further strain the already faulty part, or cause any damage to other areas of the machine. Check that safety functions of equipment are not compromised in the condition of a temporary fix. Along the vein of planning, staff must be trained to carry out the maintenance program and be valuated before they are allowed to handle it on a regular basis. The training should cover in-depth understanding of the mechanisms in order to better troubleshoot and possibly execute temporary fixes. And from the paperwork point of view, a training manual must first be documented and established so that everyone receives the same information.

EQUIPMENT MAINTENANCE IS A SYSTEM

Because each step must be carried out according to time frame and documented each time, this aspect of running a kitchen must be a well-oiled system to ensure not only food safety, but safety of its users and the impact it has on the operation’s cost.

Many small or medium enterprises do this in the form of a physical log book. But in this age of technology, simple programs such as Excel or Access can be used to develop an individual program. Otherwise there are also dedicated soft wares to help you set in place a maintenance program. Not only is it easier to input data, it makes tracking records easier, given the increasing number of machines a commercial kitchen tends to have today. The electronic way enables you to factor in a wider range of parameters without the tedious paperwork.

Some of the things to look for in an electronic system may include:

• Maintenance scheduling

• Work procedures

• Enabling workers to key in data

• Integrating costs of maintenance e.g. downtime, spare

parts, work hours, capital etc

• Set alerts to notify when to-do items are due or past-due

An electronic system can be advantageous if managers combine it with other programs, such as sanitation schedule. Doing so helps coordinate these two important functions in achieving safety and efficiency; and carrying out both activities at the same period maximises time and resources. In conclusion, a properly written preventive maintenance program is crucial to assist managers to keep tabs on equipment maintenance and as a guideline for employees to follow, reducing the possibility of executing the wrong procedure that results in unnecessary cost to rectify.

** Example of maintenance manuals depicted in this article are for descriptive purposes only and may not reflect actual specifications as equipment maintenance requirements vary. Always check with the manufacturer’s service manual.