Have you ever wondered how chefs work harmoniously in a kitchen? That they seem to move from stations to stations and all the while churning out delicious and hot piping food on time? Chefs in your kitchen are basically the pistons that run the heart of your restaurants…but how safe and comfortable is it for them?

Have you ever wondered how chefs work harmoniously in a kitchen? That they seem to move from stations to stations and all the while churning out delicious and hot piping food on time? Chefs in your kitchen are basically the pistons that run the heart of your restaurants…but how safe and comfortable is it for them?

When every kitchen designed is as diverse and unique as every chef, mishaps and accidents do happen. It was reported by SOCSO MALAYSIA that in year 2003 alone – 13,195 accident cases were notified and reported from hotels, restaurants and also wholesale & retail.

Though it would be difficult to write down a guideline for each and every kitchen – covering a multitude of cooking techniques and style, the Department of Occupational Safety & Health (DOSH), Ministry of Human Resource, Malaysia and United Nations Development Programme (UNDP) have compiled a “GUIDELINE ON OCCUPATIONAL SAFETY & HEALTH IN THE SERVICE SECTOR” as a guideline to assist owners during the design stage that the designs are done for the practicality and comfort of the staff. And if we review the points highlighted, a smartly designed kitchen helps to reduce problems when it comes to safety and also productivity and hopefully minimizes your insurance bill.

Let’s extract the relevant information and review them.

in the section of KITCHEN DESIGN – the guideline states 4 areas of focus as a general pattern for logical planning of a kitchen.

DESIGN FOR TOOLS AND SMALLER PIECES OF EQUIPMENT

• Enough work surfaces for chefs and commis when using tools of small equipment – for example, knives and chopping boards during preparation or hand mixers or surfaces for kneading dough and resting them before baking.

• Pots and pans should also be accounted for when designing – be it when the equipment is in use and hot and when it is not in use.

• Storage of this small equipment should also be identified to maintain cleanliness or have the item stored away properly to avoid clutter.

DESIGN OF MACHINES, FURNITURE AND LARGER EQUIPMENT

• Placement of larger equipment and the design of the furniture should be done where there are no sharp corners or bends. For stoves and grills – there should also be access to cold and hot water and water disposal nearby. There should also be suitable supporting handles in the vicinity of stoves and grills, so that one is less likely to grasp hot surfaces by mistake if there is a risk of slipping.

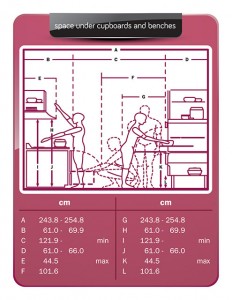

• Furniture – for example – sinks should not be too deep thus creating unsatisfactory working postures for your staff. Shelving and drawers or spaces under cupboards should also be of a reachable and safe height. Too high or too low hinders movement in the kitchen.

• These equipment should also be placed in a way that encourages easy cleaning practice in the kitchen.

“TRAFFIC” PLANNING WITHIN THE KITCHEN

• From the floor plan – layout a natural flow between the different functions such as deliveries (dry, cold and freezer), preparation, cooking and washing.

• Walking distances or crossing traffic should be avoided. Similarly steps and stairs should be avoided as these increases the danger during transportation of hot or sharp items.

WORKING TECHNIQUES

WORKING TECHNIQUES

• A manual or a Standard Operating Procedure – SOP should be prepared and studied by your staff for better understanding of your unique environment.

• A scheduled maintenance check for your equipment should also be practiced. These machines run through wear and tear everyday and keeping them in good running condition not only keeps them working but lengthen your investments.

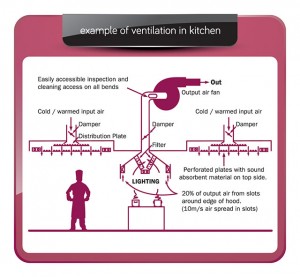

Next we look at ventilation. The biggest problem in kitchens is the heat and the humidity – radiating from hot surfaces from your cooking equipment and also heat generated from the equipment itself. And it is not just the heat – improper ventilation or exhaust systems leave the room stuffy and oily – which is not only bad for your staff but also for your equipment. Built up of grease and dirt can reduce the life span of your equipment and it also increases your maintenance bills.

there are 2 types of VENTILATION IDENTIFIED:

General Ventilation is the ventilation system that is used to take care of pollution that arises from people in the room. This can also be used for creating good thermal climate in the room by warming, cooling and /or humidifying the input air – a process called air conditioning.

General Ventilation is the ventilation system that is used to take care of pollution that arises from people in the room. This can also be used for creating good thermal climate in the room by warming, cooling and /or humidifying the input air – a process called air conditioning.

Whereas pollution from machines, frying, washing should be dealt with using a special ventilation system – identified as Process Ventilation. Process ventilation must not be mixed with the general ventilation. Output air from process ventilation should not be used as feedback air.

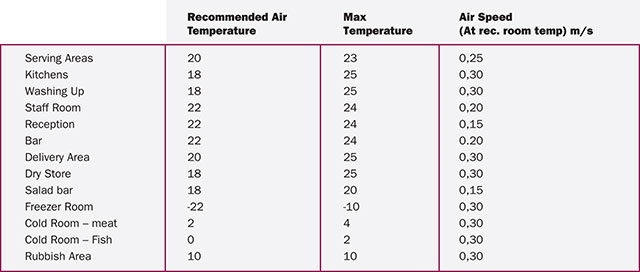

The table below shows a recommended climate limit used in hotels and restaurants.

Speak to a professional. They would be able to help you work out the necessary calculation and advise you on the best possible ventilation solution for your kitchen – making it comfortable for your staff to be productive.

Speak to a professional. They would be able to help you work out the necessary calculation and advise you on the best possible ventilation solution for your kitchen – making it comfortable for your staff to be productive.

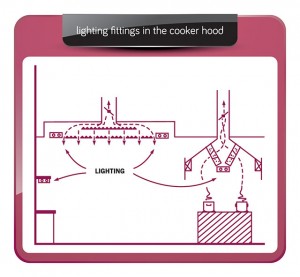

And of course, you need good lightings. Kitchens should generally have a light level of 400 lux. It should also be complemented by specific place lighting, which means light concentration on different workplaces. Lights can be hung from ceiling, mounted into stands over benches and in many cases, built into cooker hoods as per illustration attached. The lighting used should be daylight.

It is also important to remember that some lighting installed in wet areas have a certain degree of protection against the entry of water.

One other area that was specifically highlighted is also the washing area. Due to space constriction, they normally fall under these conditions:

One other area that was specifically highlighted is also the washing area. Due to space constriction, they normally fall under these conditions:

• poor environment conditions with high noise levels and high temperatures

• under wet condition and is done on slippery floors with considerable risk of slipping exposure to various chemicals

• with physical loading which is unusually high, with difficult working postures and heavy lifting

To counter these issues, the following were suggested:

√ have sufficient storage so that peak loadings would be safely stored and evened out

√ there should be access to washing arms or rinsing arms which eases when washing heavy and bulky equipment

√ having a pressured spray helps without excessive scrubbing and use of chemicals

√ to reduce contact of chemical, try to automate cleaning work with dishwashing machines. And these dishwashers are best placed in a separate room

Also when it comes to washing, a quick mention on your flooring. Floors should be designed slip free and using easy to clean material. It should also have sufficient slope for water to run and drain out to avoid water pools forming on the floor.

But on top of it all, invest in proper footwear and attire for your staff. Accidents do happen, as we are only human. But implementing smart guidelines would help deter them and bring about a safer and comfortable working environment for you and your staff in your kitchen.